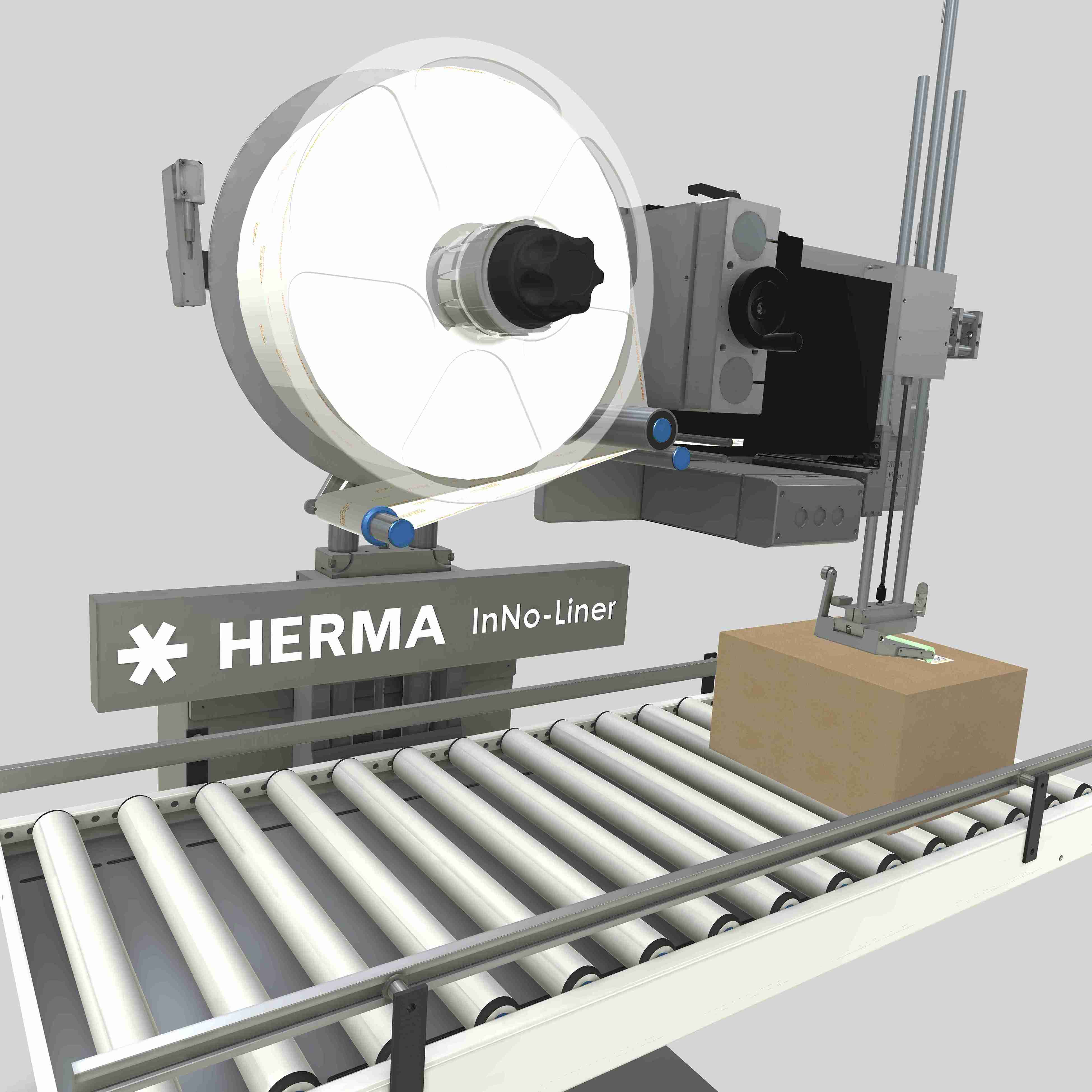

Over 100 billion parcels are shipped worldwide every year - and the trend is rising - almost all of them with a shipping label. Those who achieve savings here in the labelling process secure important competitive advantages at a crucial point in the logistics chain. And they can do so enormously with the new HERMA InNo-Liner system, for which a patent application has already been filed. This is because it completely eliminates the need for the siliconized backing material previously required. HERMA also won the German Packaging Award in the sustainability category in 2019 with the HERMA InNo-Liner System.

Linerless paper and special adhesive for linerless

Labels

The all-new HERMA InNo-Liner system is the product of a pioneering performance by the company and its long-established leading edge in the production of self-adhesive materials based on multi-layer technology. This advanced applied science demands the simultaneous application of two adhesive layers. The 82S adhesive is not at all sticky at first. It is activated within a fraction of a second as the label is dispensed and then immediately and permanently sticks to the substrate.

The material offers absolute process reliability. Its stability has been verified both in the climate lab and in practical printing and processing tests.

Current range:

Why HERMA InNo-Liner?

- Benefits compared to siliconised linerless

- Highly diverse materials

- Multicolour printing possible

- Various printing techniques possible

- Free from silicone

- Permanent final adhesion

- Accelerated cycle speeds

- Lower costs

- Cut edges do not stick to each other

- Reduced downtimes

- Benefits compared to self-adhesive labels

- No liner

- More material on each rol

- Less warehousing space

- Fewer roll changes

- Low transport volume

- More efficient usage

- No waste disposal costs

- Avoidance of torn backing paper

- Lower costs

- Variable label length

- Ecological benefits

- No liner waste

- Lower transport weight

- Lower transport volume

- Reduced CO2 emissions

- Less material consumption*

- Free from silicone

*(No label feed or waste stripping)

Linerless paper: labels without liner

Around the globe, labelling in the shipping industry currently leaves behind millions of tons of liner material that is completely useless after the labelling process. The complete elimination of this residue also means the complete elimination of the previously necessary and expensive disposal or recycling processes.

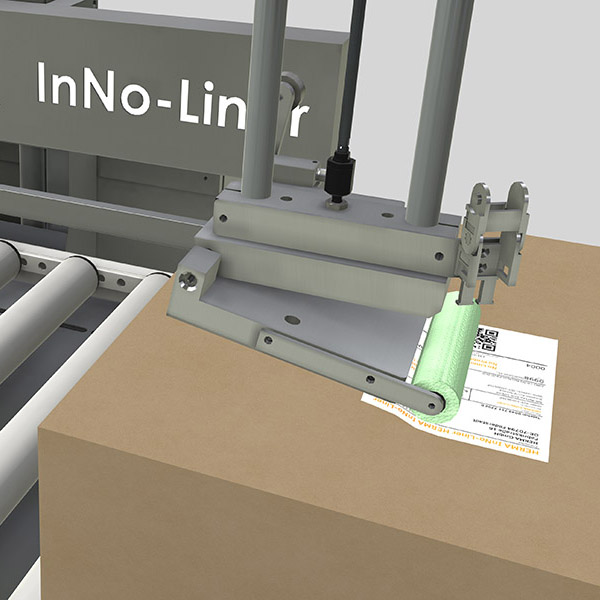

Users, print shops and the environment can also rejoice for other reasons: because there is no liner, more labels fit on a roll, which in turn are easier to transport and take up less space in the warehouse. The material is absolutely process-safe. Both in the climate laboratory and in practical tests during printing and processing, it delivers the required resistance. The HERMA InNo-Liner system easily manages the cycle speed usually required for labels in A5 or A6 size, pre-printed in colour if required. And the costs are just as low as for a conventional self-adhesive label - while the costs for disposing of the liner material are completely eliminated.

82S adhesive - the basis for linerless Self-adhesive Material

The new 82S adhesive is a permanent, water-activated adhesive. It was specially developed for applications on cardboard and comparable paper-like substrates. It is therefore particularly suitable for use in the logistics sector, e.g. as shipping labels and for marking on absorbent substrates. In combination with suitable dispensing equipment, marking speeds similar to those normally achieved in the print-and-apply sector can be achieved.

The 82S pressure-sensitive adhesive is initially deactivated and the material therefore does not adhere. Within fractions of a second, the adhesive is then activated during dispensing and immediately adheres permanently. Both in the climate laboratory and in practical tests during printing and processing, the material delivers the required resistance - it is absolutely process-safe.

Linerless papers: available standard materials

The InNo-Liner - Adhesive 82S can be processed on common printing and roll cutting machines. Adhesive 82S can be safely used for the back coating of labels for the labelling of foodstuffs for storage at room temperature. It may be in direct contact with dry and fatty foods. In addition, contact with moist foodstuffs is permissible.

In principle, other combinations with coated papers are also conceivable, please feel free to contact us (greater variety of materials than with conventional InNo-Liner).

Further CO2 savings in the process

The saving of the release liner alone ensures 45% less CO2 emissions compared to self-adhesive labels.

In addition, there are further CO2 savings in the process. For example, further material savings are achieved by eliminating matrix waste at the label material. For a narrow roll width of 333mm, this results in a saving of approx. 12%. Further savings of approx. 3% can be achieved through reduced storage and handling costs. Overall, the HERMA InNo-Liner system can save around 60% of CO2 compared to a classic self-adhesive label.

Of course, this is only a rough sample calculation based on common dimensions. Our experts will be happy to advise you and calculate the saving potential for your specific application. Please contact us non-committal using the contact form.

HERMA InNo-Liner - A Success Story as far as Down Under

To achieve its 2025 sustainability targets, Hanes Australasia is now relying on the HERMA InNo-Liner system, among other things.

The company "Down Under" was convinced by the impressive cost-effectiveness of the InNo-Liner system compared to the labels and machines previously used. In particular, the elimination of waste, which occurs with conventional labels in the form of the backing material, was a major saving.

The InNo-Liner system is already causing a stir in Australia: At Hanes, the linerless label is already under the vacuum suction plate of the linear unit. Here, the non-adhesive pressure-sensitive label is activated by the micro-atomization unit underneath.

Discover more sustainable Self-adhesive Materials from HERMA

To support the recycling process, HERMA has developed a wash-off adhesive that achieves a film label wash-off rate of 100 percent for PET bottle recycling.

HERMA also pays attention to the sustainable use of raw materials, which is why the HERMAnature fieno label material consists largely of grass. Thanks to the innovative processing of dried fibers for paper production, up to 97 percent energy and 99 percent water can be saved compared to the use of wood pulp.

Discover more sustainable solutions from HERMA Self-adhesive Material

Wash-off adhesive - Wash-off pressure sensitive adhesive

With a unique, comprehensive chain of expertise: from self-adhesive material and labels to high-performance applicators. Leading companies all over the world rely on HERMA to supply them with high-quality labelling systems. With our extensive knowledge in the area of self-adhesive labelling, we ensure that the labelling and identification of products and packaging runs smoothly in all aspects.

Curious to find out more?

Discover exciting press releases on this topic and more – simply click on the button to find out more!