The requirements for labelling pharmaceuticals are higher than in almost any other industry. This is because for the highest possible security in the labelling of medical products and pharmaceuticals, such as vaccine labelling, different technologies for printing, identification, labelling and inspection must interact perfectly in a very confined space.

Below is a description of HERMA's structure and approach to pharmaceutical projects.

Special team at HERMA for your pharmaceutical labelling needs

In order to meet the requirements of customers, legal regulations and GMP regulations, we have created a special team consisting of sales, internal sales, project management and service.

Project sales

- Detailed discussion of customer requirements and production conditions

- Obtaining a list of requirements (URS) and initial clarification with the customer

- Discussion of the requirements with technical internal sales and project management

Technical and commercial internal sales

- Detailed clarification and commenting of the catalogue of requirements

- Development of an individual solution concept for customer-specific requirements based on the requirements catalogue

- Preparation of an quotation for the customer

Project management

- Supervision of the project after the order has been placed, through the manufacture of the machine up to acceptance

- Internal & external communication

- Testing and validation of the machine before and at the customer acceptance test

Service

- Installation & setup of the machine at the customer's site

- Testing of the interfaces

- Testing and validation of the machine before and during the site acceptance test (SAT)

- Maximise the uptime and service life

4-phase process for the procurement of a labelling machine for pharmaceuticals

At HERMA, the process of a labelling machine for pharmaceuticals can essentially be divided into 4 phases. The enquiry phase, the order phase, an acceptance and installation phase, and the life cycle and utilisation phase.

Enquiry phase

In the first step, the requirements for the machine and the production conditions are discussed in detail.

We ensure that all enquiries are

- individual

- GMP-compliant

- quickly

- and transparent.

We place particular emphasis on transparency and comprehensibility in the development of our offers.

Order phase

Now the actual production and implementation of each individual labelling solution begins.

The technical internal sales team starts the internal order writing and creates the so-called specification sheet.

In the next step, our construction department creates the 3D model of the machine.

After the customer's approval, the construction of the system begins in one of the most modern manufacturing facilities for labelling machines.

Acceptance and installation phase

After finishing the machine, the acceptance and installation phase follows.

- During the Factory Acceptance Test (FAT) at our premises, the machine is validated together with our project managers and technicians.

- This is followed by installation and setup at the customer's site by our technicians and the Site Acceptance Test (SAT).

- In addition to the line performance, the interfaces to other machines in the line are also tested, for a smooth commissioning.

Life cycle and utilisation phase

At HERMA, the process does not end with the delivery of the machine. Our team of service experts and product management is at your side throughout the entire service life of the machine, helping you to maximise its useful and operational life.

In close contact with our customers, we strive to constantly improve our products and develop them further for the future.

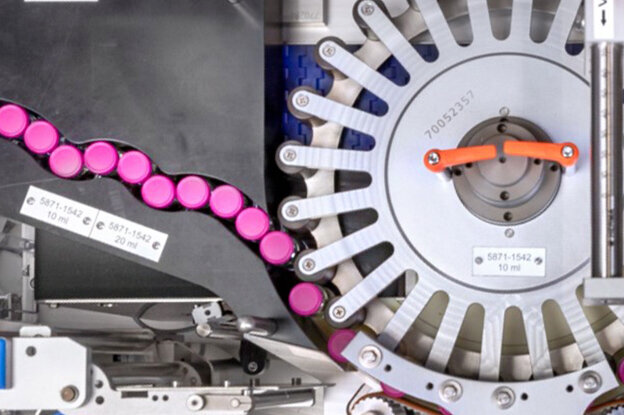

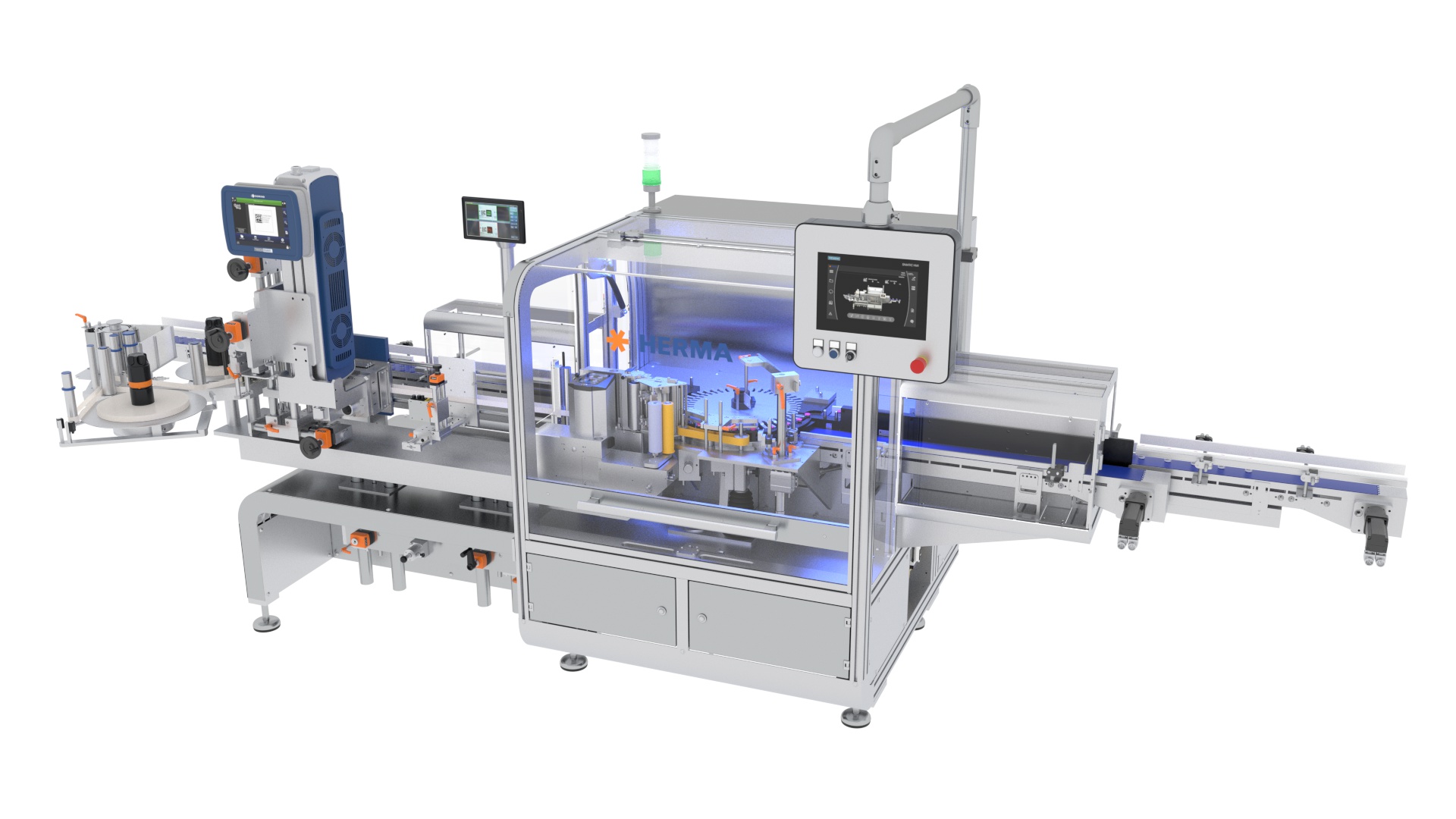

HERMA labelling solutions for the pharmaceutical industry

Reliable, flexible and highly productive: With us, you will find powerful labelling machines to suit your requirements for labelling your pharmaceuticals. The 132M HC, which is also shown in the videos above, provides wrap-around labelling of vials at high-speed. Other labelling machines for the labelling of pharmaceutical products are the 362E TE, which offers a particularly economical solution for tamper-evident labelling, as well as the 362M, which ensures precise side and optionally wrap-around labelling with unmatched precision - HERMA is the right choice for every labelling task.

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.

![[Translate to English:] Rundum-Etikettierer 132M](/fileadmin/Etikettierer/kacheln/HERMA-132M.jpg)

![[Translate to English:] Rundum-Etikettierer 040M](/fileadmin/Etikettierer/kacheln/HERMA-040M.jpg)

![[Translate to English:] Zweiseiten-Etikettierer 362M](/fileadmin/Etikettierer/kacheln/HERMA-362M.jpg)

![[Translate to English:] Zweiseiten-Etikettierer 362E](/fileadmin/Etikettierer/kacheln/HERMA_362E_Kachel.jpg)

![[Translate to English:] Tamper-Evident Etikettierer 362E TE](/fileadmin/Etikettierer/kacheln/Kachel-362E_TE.jpg)

![[Translate to English:] Rundum-Etikettierer 211 HC](/fileadmin/Etikettierer/kacheln/HERMA_211_HC-Kachel.jpg)

![[Translate to English:] Rundum-Etikettierer 211](/fileadmin/Etikettierer/kacheln/HERMA-211-Rundum-Etikettierer-350.jpg)

![[Translate to English:] Obenauf-Etikettierer 414](/fileadmin/Etikettierer/kacheln/HERMA-414-Obenauf-Etikettierer-350.jpg)