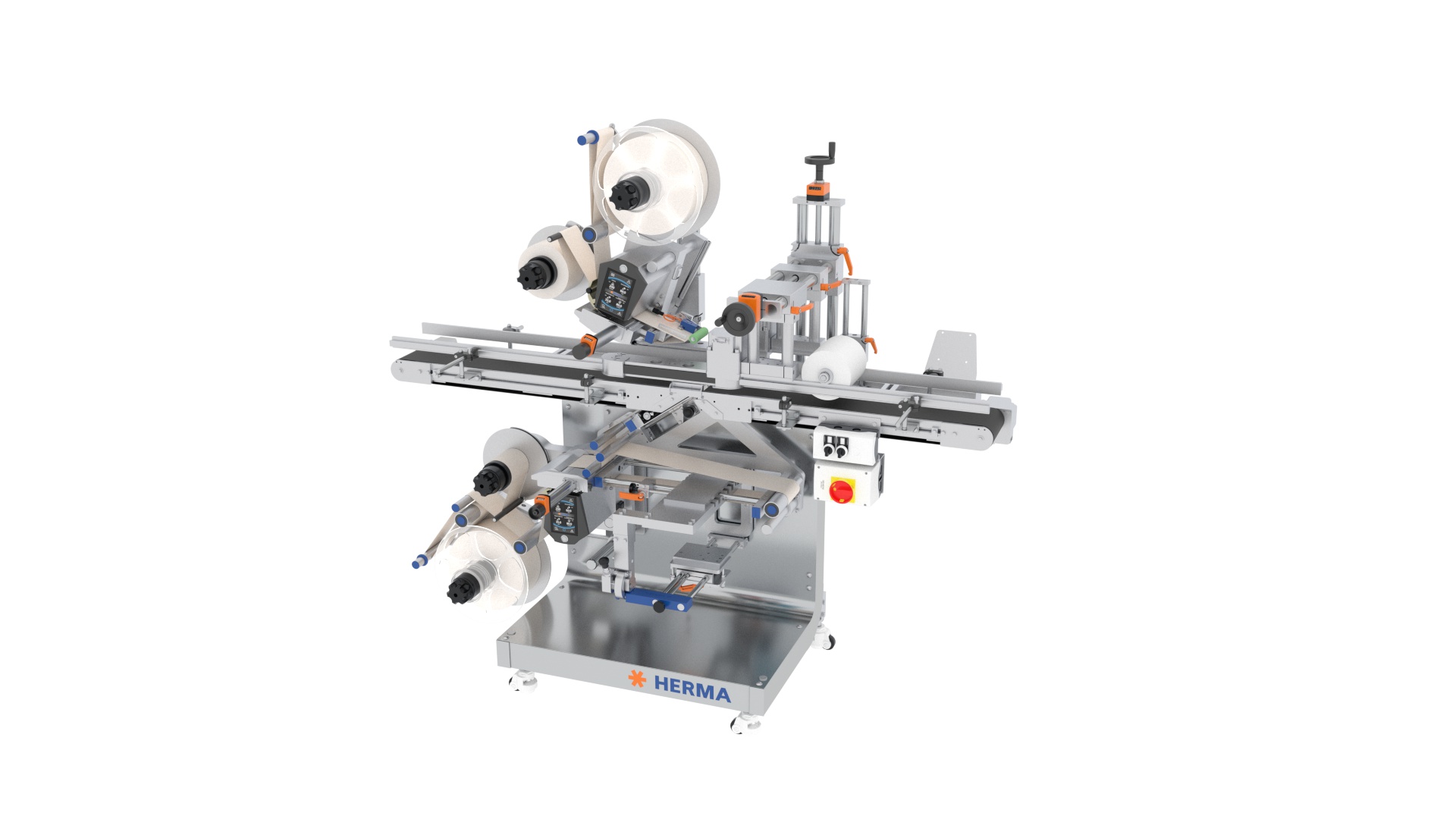

HERMA supplies the perfect labelling machines for these challenging tasks. They not only meet the high demands of our customers, but also come with a tailored servicing concept that guarantees the highest level of reliability, flexibility and operability for the series production of large quantities of products.

- Whether you need wrap-around labelling, side labelling, top and bottom labelling or seal labelling, we have the perfect solution for all kinds of applicators.

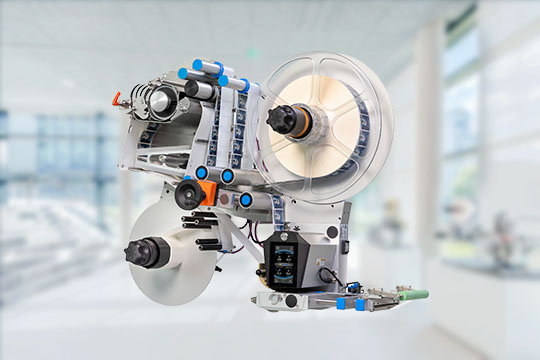

- The integrated HERMA 500 guarantees absolute dispensing precision – even with particularly challenging four-sided labelling: a precisely and cleanly applied label is a marker for the high quality of the product in the packaging!

- With just a few manual interventions, our application solutions can be adjusted to other product sizes in a matter of minutes

- Our labelling machines feature a compact stainless steel design that fully meets food industry requirements and makes them suitable for use in practically every production environment

- Thermal transfer printers or hot foil printers can be integrated with ease to print variable data such as batch numbers and use-by dates

What matters when labelling food products:

- Machine surfaces that are easy to clean

- Food-safe materials for product contact, food-safe conveyor belts

- Format parts that can be changed without tools

Labelling Businews

Read edition #002 of our industry magazine, featuring the topic of “Labelling in the Food Industry”

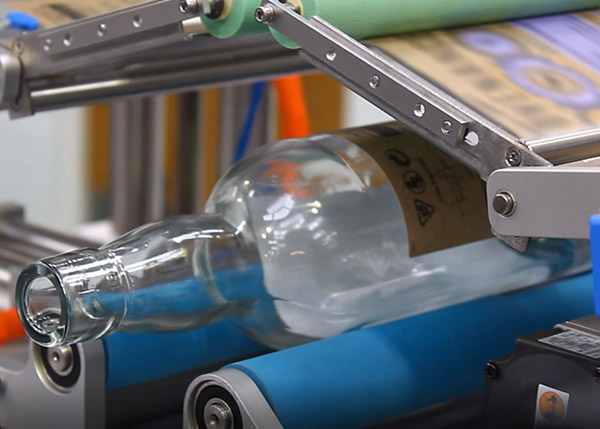

Special labels for reliable identification in the food and drinks industry and common types of packaging

If you want to use special labels for resealing a package, seal and tear labels, labels with pull tabs, labels for marketing campaigns, complex booklet labels with consumer information or high-quality transparent labels, you need application equipment that is perfectly tailored to the job. Brand-name items, in particular, demand the highest precision for such processes. Applying even relatively simple labels with variable data can be a challenge if the labelling occurs under difficult conditions. In the food and beverage industry, this can include moist and cold surfaces, warm containers or even frozen products.

Learn more about labels for food labelling

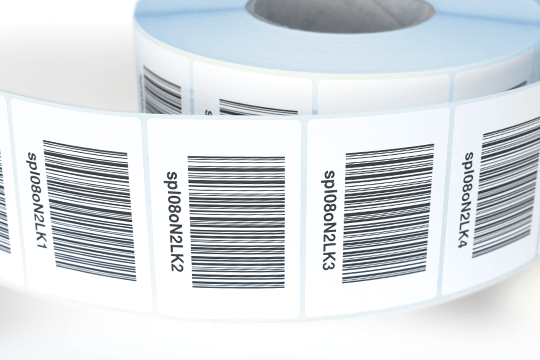

Food labelling is subject to strict requirements: for many foods, legislation stipulates that their label or packaging must contain information about ingredients and nutritional values. Different foods also have different requirements for their labelling: Depending on the packaging and contents, the right label must be selected to ensure it can be securely attached to the packaging and remains adhered.

For instance, all foodstuffs should include the Global Trade Item Number (GTIN), which, together with the barcode, is an internationally distinctive product identifier that not only lets you identify the items, but also lets you register goods in checkout and stock management systems.

Ultimate performance thanks to the HERMA 500

The new HERMA 500 gives you peak performance in every regard. Innovative touchscreen menu navigation and cutting-edge interfaces tailored to Industry 4.0 are just some of the highlights of this pioneering technology.

Ease of use

With their ease of use and ability to process a wide range of products, HERMA labelling machines can meet any requirements of food and beverage manufacturers.

Printing variable data

Printers can easily be integrated to apply variable for food labelling.

Adapted to your requirements

The systems are sturdy and built from high-quality stainless steel, making them easy to clean and able to meet the strict requirements of the food and beverage industry. The machines can be supplied with a variety of conveyor belt dimensions, which means they can be configured for a huge range of applications.

Flexible installation locations

Our HERMA labelling systems are low maintenance, exhibit high labelling accuracy, can be modified to fit any installation situation and can be integrated into virtually any packaging line.

Pillow bag labelling

Pillow bag labelling is also no problem for our labelling solutions. In most cases, the space available within the existing frame is extremely limited despite the high performance parameters required. The applicator must also work in complete synchronisation with the speed of the pillow bag system. Our labelling machines can do all that with ease.

Our promise: A belief-based added value in food labelling

Find out here how our values have a lasting impact not only on food labelling, but on all our labelling solutions:

With a unique, comprehensive chain of expertise: from self-adhesive material and labels to high-performance applicators. Leading companies all over the world rely on HERMA to supply them with high-quality labelling systems. With our extensive knowledge in the area of self-adhesive labelling, we ensure that the labelling and identification of products and packaging runs smoothly in all aspects.

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.