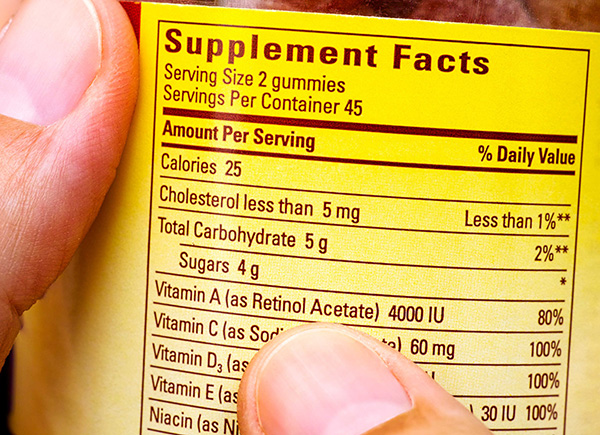

Confectionery products range from sweets, e.g. chocolate in any form including bars, pralines and truffles, to candies, fruit gums and licorice, right through to biscuits, waffles and other sweet pastries. The most commonly used types of packaging are folding boxes, slip lid solutions, cans, pillow bags and other film-based solutions. Especially when packaging in transparent film, labels are often used to convey all branding information, including the list of ingredients and the nutritional information. In other types of packaging, labels are primarily used for promotional purposes, opening/closing or sealing or to indicate the best-before date and batch number.

- In the case of confectionery, a single product or piece of packaging often incorporates multiple labels for different purposes. It is therefore not uncommon to have a combination of wrap-around labelling, side labelling, top & bottom labelling and closure labelling.

- Since the labelling of sweets of all kinds usually takes place at the end of a packaging process, there is sometimes little space for an applicator or labelling machine.

- In addition to the pre-printed label, additional variable data often has to be printed during the labelling process, such as the expiry date.

The key factors when labelling confectionery

When it comes to the labelling of confectionery, very specific tasks have to be mastered. In order to fulfill these tasks, labelling machines require three properties in particular: cleaning capability, precision and reliability.

-

Optimal cleaning

In order to rule out contamination and cross-contamination, easy-to-clean machine surfaces and easy access to the relevant parts are essential.

-

High precision

Since confectionery labels are often an important branding element and can determine the success of the product at the point of sale, a high degree of precision is required, especially where packaging tends to be unstable or the labels have unusual shapes.

-

Reliable processes

Since confectionery is often produced in large quantities, high-performance, reliable applicators are a necessary requirement for many applications. For particularly efficient production, it must be possible to label a high number of products without long periods of downtime.

-

Quick retooling

To allow products of different shapes to be labelled efficiently on the same production line, HERMA labelling machines can be adapted to different product sizes in just a few simple steps.

Special labels & common types of packaging

Choosing the perfect combination of packaging type and label has a major impact on the success of the product, not least in terms of how consumers perceive certain confectionery (brands).

These labels come into use

Labels on confectionery provide information about ingredients and nutritional values, create an attractive brand image, reassure consumers that the packaging has not been tampered with or provide information about specific promotions. That is why such a large number of label variants are used, sometimes even on the same product. The labels are usually opaque and completely printed, but may be transparent for specific applications. The most common label types are:

The following types of packaging are used

Confectionery packaging is used for optimal, efficient transport, hygienic, food-safe and distinctive product presentation at the point of sale, as well as safe storage of the products even after the pack has been opened. Incorporating packaging elements that are as sustainable as possible is also becoming increasingly important. The most common types of packaging are:

- Folding boxes

- Pillow bags

- Cans

- Slip lid solutions

- Blisters

- Thermoforming and tray solutions

Labelling of confectionery with HERMA labelling machines

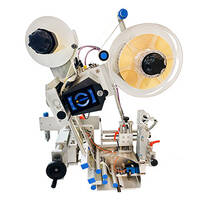

HERMA's applicators and labelling machines cover the entire spectrum of confectionery requirements. Extremely flexible, produced to a high quality standard, exceptionally reliable and equipped with future-proof technology, these devices always offer a high level of investment security. Thanks to an intuitive PLC controller, food items can be labelled efficiently and downtimes eliminated, for example when replacing label rolls.

- Whether you need wrap-around labelling, side labelling, top & bottom labelling or closure labelling – HERMA can provide the perfect labelling solution for any confectionery product.

- Thanks to their compact design, HERMA labelling machines can be integrated into almost any production environment.

- A food-safe structure made of stainless steel guarantees the best possible hygiene standards.

- The modular design ensures that almost all common thermal transfer printers or hot-foil printers can be installed in order to print variable data such as batch numbers and expiration dates.

- By incorporating a large number of different peel plates, the integrated HERMA 500 ensures absolute precision and safe and gentle product handling in every labelling and packaging machine, regardless of label size or shape.

- The HERMA 500 achieves a labelling performance of up to 50 meters per minute even without a engine-driven winder – a considerable cost advantage.

- Many format parts can be changed particularly quickly on HERMA labelling machines since they do not require tools.

Labelling Businews

Read issue #002 of our industry magazine to find out more about the “Labelling of chocolate or pillow bags.”

Labelling Businews

Read issue #004 of our industry magazine to learn more about the “Labelling of clamshell packaging.”

Labelling machines used for labelling confectionery

HERMA applicators and labelling machines are always the optimal solution, especially when it comes to demanding applications like labelling confectionery. The HERMA 500 MB uses a moving peel plate to apply decorative labels with great care and precision. The HERMA 500 VFFS or HFFS, on the other hand, can be integrated directly into pillow bag systems due to its space-saving, compact dimensions. With the 452C, 552C and 652C machines for top labelling, bottom labelling or a combination of the two, HERMA sets new standards in cost-efficiency. Closure labelling is also becoming increasingly popular, especially for blister packaging. Machines such as the 752C are designed to apply a single label to the bottom, front and lid and optionally to the back of the packaging, thus closing the package securely in a single pass. The 152C, in contrast, offers exceptional accuracy in wrap-around labelling. Whereas, the key feature of the 362E is the fact that this machine can be converted from standard two-sided labelling to wrap-around labelling with little effort.

Our promise: A belief-based added value in confectionery labelling

Find out here how our values have a lasting impact not only on sweets labelling, but on all our labelling solutions:

Your strong partner for labelling of confectionery

HERMA is a reliable and experienced partner to have at your side. We are known the world over as an innovative specialist for self-adhesive technology.

![[Translate to English:] HERMA Etikettiermaschinen Gebude in Filderstadt](/fileadmin/Etikettierer/Branchen/OEM/HERMA_Labeling_Machines_site_in_Filderstadt.jpg)

|

|

HERMA has been delivering quality for over 110 years and has more than 50 years’ experience in developing and manufacturing applicators. |

|

|

We are constantly setting technical standards in labelling technology and are among the world’s leading innovators. |

|

|

International availability is ensured through our global partner network as well as subsidiaries in Europe and the US. |

|

|

Over 250 HERMA experts focus solely on the field of labelling and are able to provide you with high-level advice. |

|

|

All-round carefree package: from advising you on self-adhesive material and labels, labelling tests and machine demonstrations right through to assisting you with integration into your machine and with the labelling process. |

Contact

Do you face particular challenges when labelling confectionery? Do you want to find out more about sustainable labelling technology? Would you like to see HERMA applicators and labelling machines in action? Then just send us a short message. We'll get back to you as soon as possible.

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.

Success stories from the confectionery industry

There are many reasons to choose HERMA applicators and labelling machines. See which factors were most important to our customers when it came to labelling confectionery products.

![[Translate to English:] Marketing-Promotionsetiketten](/fileadmin/Etikettierer/Anwendungen/HERMA_Labeling_Machines-application_Marketing-Etikett.jpg)