Semi-automatic labelling machine:

HERMA wrap-around labeller 211 HC for healthcare

211 HC: Feeding demand for personalised medical care

- The wrap-around labeller 211 HC reliably processes even the smallest batches and products that tend to tip over

- Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes

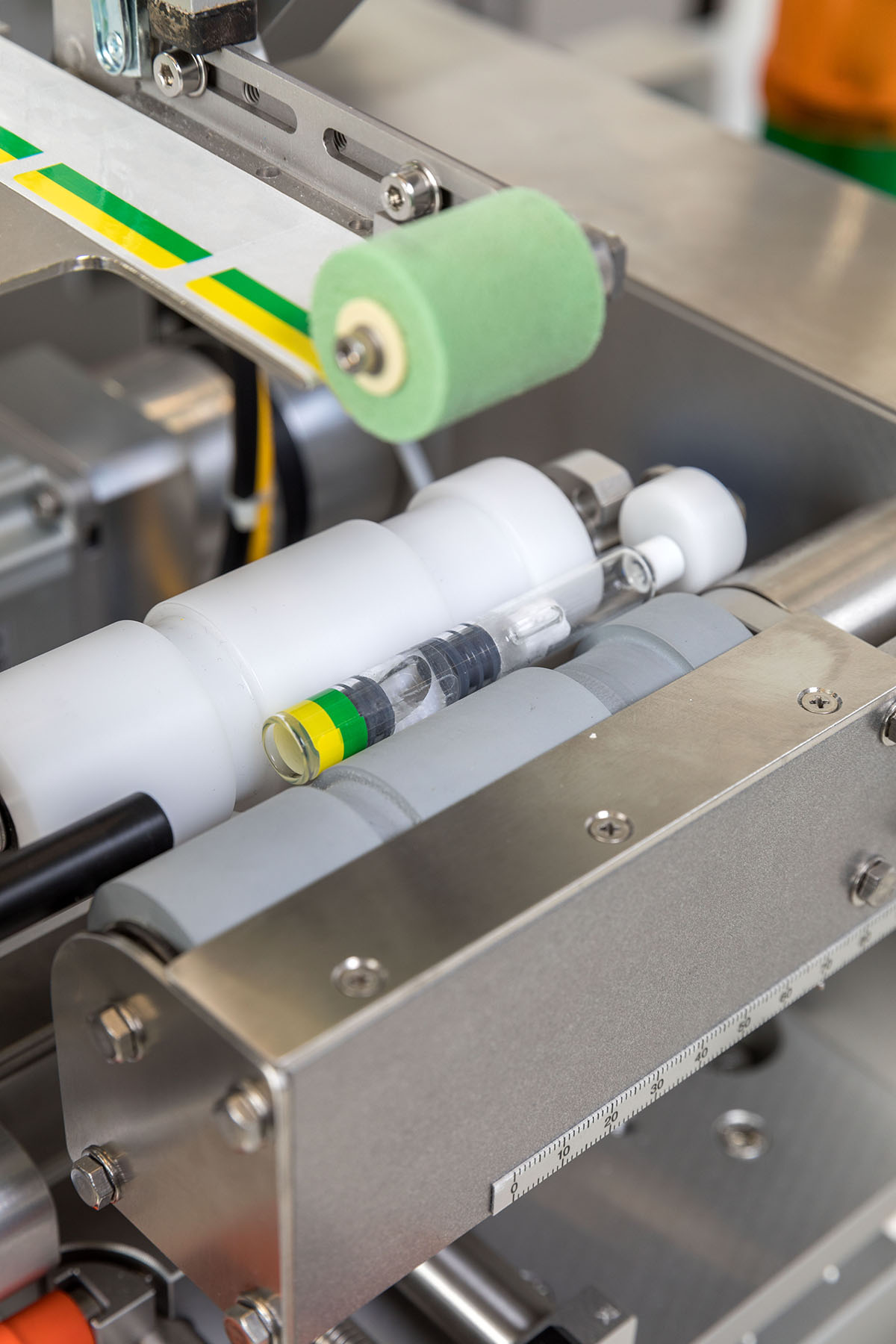

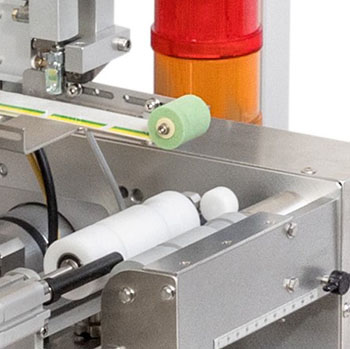

- Labels are applied by rotating these products horizontally between two motorised rollers and the pivot peel plate with application roller

- The semi-automatic labelling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification

- Optionally available with the innovative bad label return for the reliable removal of bad labels

- The new 211 HC is therefore tailor-made for processing healthcare products

The 211 HC processes small batches efficiently and reliably

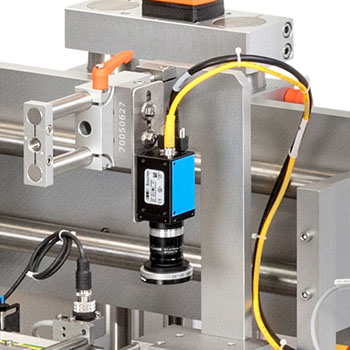

The ability of fully automatic labelling machines to offer cost effectiveness and process reliability is soon compromised if it comes to small batch sizes and products that tend to tip over, such as small vials, syringes and cartridges. For these types of products, the semi-automatic wrap-around labeller 211 HC combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications. Thanks to a printer for variable data and codes, and a camera for print and code verification this machine is ideally suited for healthcare products.

And this is how it works

The 211 HC rotates the cylindrical and dimensionally stable products horizontally between two motorised rollers and the pivot peel plate with application roller. The label is dispensed onto the rotating product and applied in the correct position by the application roller. For both, height and spiral alignment, the tolerance is no more than plus or minus one millimeter. Once the label has been applied, the pivot peel plate returns to its home position and the labelled product is removed from the labelling station by hand. In case of an error signal of the checking system, the machine stops and issues a message. The defective label can then be removed manually at the peel plate. A variety of thermal transfer and laser printers can be used to print variable information, such as a use-by date or batch number, before the labels are dispensed. All conventional camera systems can be integrated into the machine for verifying correct printing and codes. If products with a variety of dimensions are to be labelled, the available format parts enable a quick changeover of the machine.

Best results & useful options

|

|

With its flexible adjustment options, the wrap-around labeller 211 HC is perfect for small glass vials, syringes, cartridges and pens, which are difficult to label because of their shape, size or weight. |

|

|

As well as a thermal transfer printer for variable data – typically the batch number and expiry date – the pharma equipment includes the integration of various camera systems to verify printing and codes. |

|

|

Cylindrical and largely stable in form products are rotated in a engine driven roller prism. The label is then precisely dispensed by the pneumatic pivot peel plate and applied to the product by a roller. |

|

|

In addition to the option of integrating a thermal transfer printer, the machine can be prepared for, or fully equipped with a laser printer for variable data and codes. |

|

|

For labelling frequently changing products with different dimensions, format parts with quick-change unit can be supplied as an option. This allows easy format changes at any time without long changeover times. |

|

|

The 211 HC wrap-around labeller offers a wide range of additional options if required, such as aligned wrap-around labelling to a defined scan mark, pneumatic product fixing, and a bad label return function. |

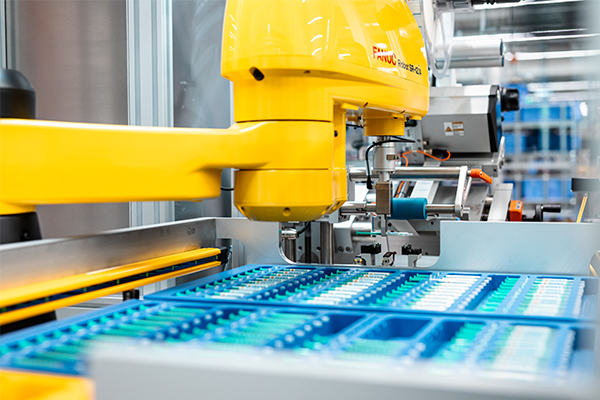

Minimise downtimes even further and increase efficiency with robot-assisted labelling

With the robot-assisted labelling cell 211R HC, HERMA shows how the challenges of wrap-around labelling of label material can be solved even more efficiently. The use of robot technology optimizes efficiency by reducing downtimes and achieving consistently high output over a long period of time and with a high throughput.

Technical details

|

Labelling type: |

Wrap-around labelling |

|

Product specifications: |

Cylindrical, largely stable in form |

|

Product dimensions: |

10 - 70 x 30 - 130 mm (D x H) |

|

Label dimensions: |

15 - 80 x 30 - 220 mm (W x L) |

|

Capacity: |

Up to 15 products/minute |

|

Power supply: |

230 V, 50 Hz, 1 phase |

|

Compressed air supply: |

6 bar |

|

Printers: |

Various hot-foil, thermal transfer and laser printers (optional) |

|

Components: |

Control panel with 7 inch touchscreen, signal column, two-handed start, applicator, printer, print check, roller prism, Siemens control |

|

Options: |

Code check, bad label return, pneumatic product fixing, aligned wrap-around labelling, format parts with quick-change unit, Allen-Bradley control, movable version, qualification |

|

Note: |

If optional features are chosen, the above data may vary |

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.