Labelling machine:

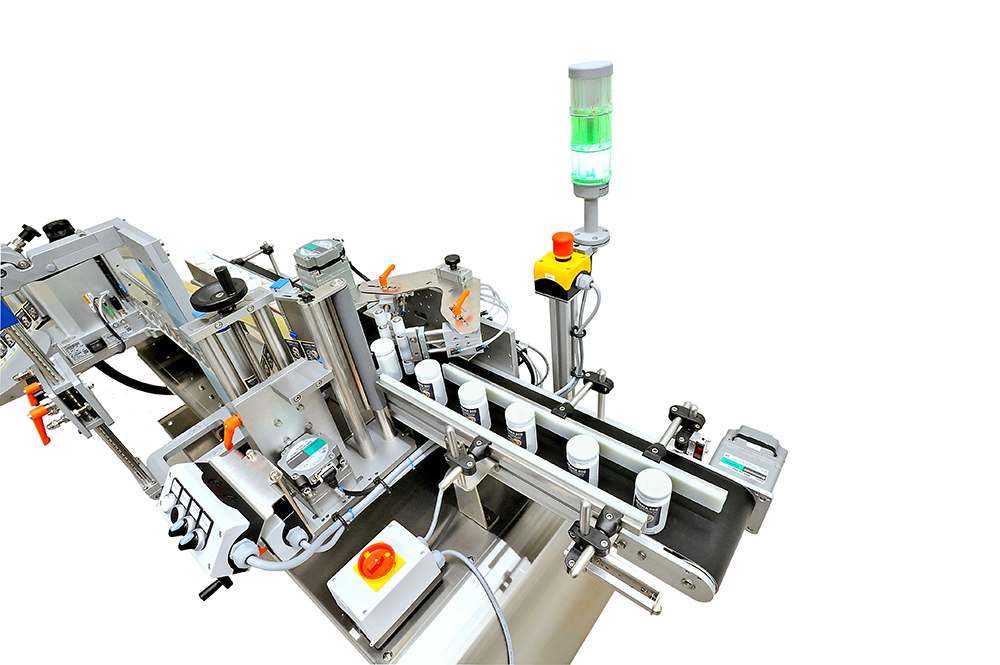

HERMA Wrap-around labeller 152C

HERMA wrap-around labeller 152C: precise labelling at low cost

- Equipped with the high-performance labeller HERMA 500, it is suitable for up to 200 cylindrical products per minute

- The easy-to-maintain solution with a folding belt and back pressure plate offers amazing performance and a fast return on investment

- Most adjustments can be made without tools with little time required

- With the optional roller prism technology, even spiral misalignment is almost completely eliminated; even aligned labelling succeeds perfectly

- Clean Design with closed holes, minimum gaps and grooves, and rounded corners protects the 152C from contamination and makes it easy to clean and maintain

- Installation of a printer unit such as a hot stamp or thermal transfer printer is possible without any problems

- Is now available much faster due to the Clean Design and digitized ordering processes, optionally in EU or US versions.

Why should precision be a matter of price?

This machine is a bestseller: It focuses on the essentials, provides an extraordinary performance, and is quickly amortised. This is ensured by a high-performance applicator and a maintenance-friendly solution featuring a wrap-around belt and a counterpressure plate. If precision is required for especially tricky products, optional roller prism technology can be employed.

The 152C ensures precise, cost-efficient labelling

Best results & useful options

- By choosing the new HERMA 500, you can expect top performance in every aspect. Highlights of this technological flagship include a touchscreen with an innovative menu navigation and state-of-the-art interfaces.

- Featuring a wrap-around belt and a counterpressure plate, the machine is suitable for a very wide range of cylindrical products.

- The 152C saves precious time. Most settings can be adjusted without tools.

- Spiral misalignment is practically eliminated through the use of a roller prism. Even labelling in orientation is not a problem.

- Printing units like hot-foil or thermal transfer printers can be easily integrated.

- The 152C masters various mounting conditions and production environments. The conveyor belt is available with a width of 100 or 150 mm, at a length of 1,540 mm.

Why Clean Design can advance your business

With Clean Design, HERMA is taking its successful modular concept for labelling machines to a whole new level. The advantages are numerous and range from more efficient ordering processes to greater modular flexibility and from ease of cleaning to improved sustainability. Learn more about our Clean Design.

Available faster

Digitized configuration and ordering processes enable shorter response and processing times, so that our customers can very quickly put their machines into production.

Perfectly equipped

A number of useful features are included as standard with Clean Design machines. They are therefore more cost-efficient and readily available.

More choice

Clean Design gives you more options for every application. You can choose between the equivalent EU and US versions, or between an aluminum frame with stainless steel plates and an optional full stainless steel version.

Optimised cleaning

With their hygienic construction, Clean Design machines are easy to clean and maintain.

Sustainable approach

Thanks to the elimination of machine-specific bench pedestals, the use of universal function modules and the digitisation of the configuration and ordering processes, Clean Design is a step toward greater sustainability.

Technical data

|

Labelling type: |

Wrap-around labelling |

|

Product specifications: |

Cylindrical and free-standing |

|

Product dimensions: |

Wrap-around labelling with belt: 30 - 150 x 30 - 250 mm (D x H) / Wrap-around labelling with roller prism: 20 - 100 x 30 - 250 mm (D x H) |

|

Label dimensions: |

15 - 240 x 30 - 315 mm (W x L) |

|

Capacity: |

With wrap-around belt up to 200 products/minute / With roller prism up to 75 products/minute |

|

Power supply: |

230 V, 50 Hz, 1 phase, 110 V, 60 Hz, 1 phase (optional) |

|

Compressed air supply: |

6 bar |

|

Printer: |

Various hot-foil printers and thermal transfer printers (optional) |

|

Components: |

Conveyor belt, side guides for products, roller-type separator, applicator, wrap-around belt with counterpressure plate |

|

Optional features: |

Transfer plates at infeed and outfeed, movable version, digital position indicators, roller prism with wrap-around roller, aligned wrap-around labelling, outfeed jam check, signal column |

|

Note: |

If optional features are chosen, the above data may vary |

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.