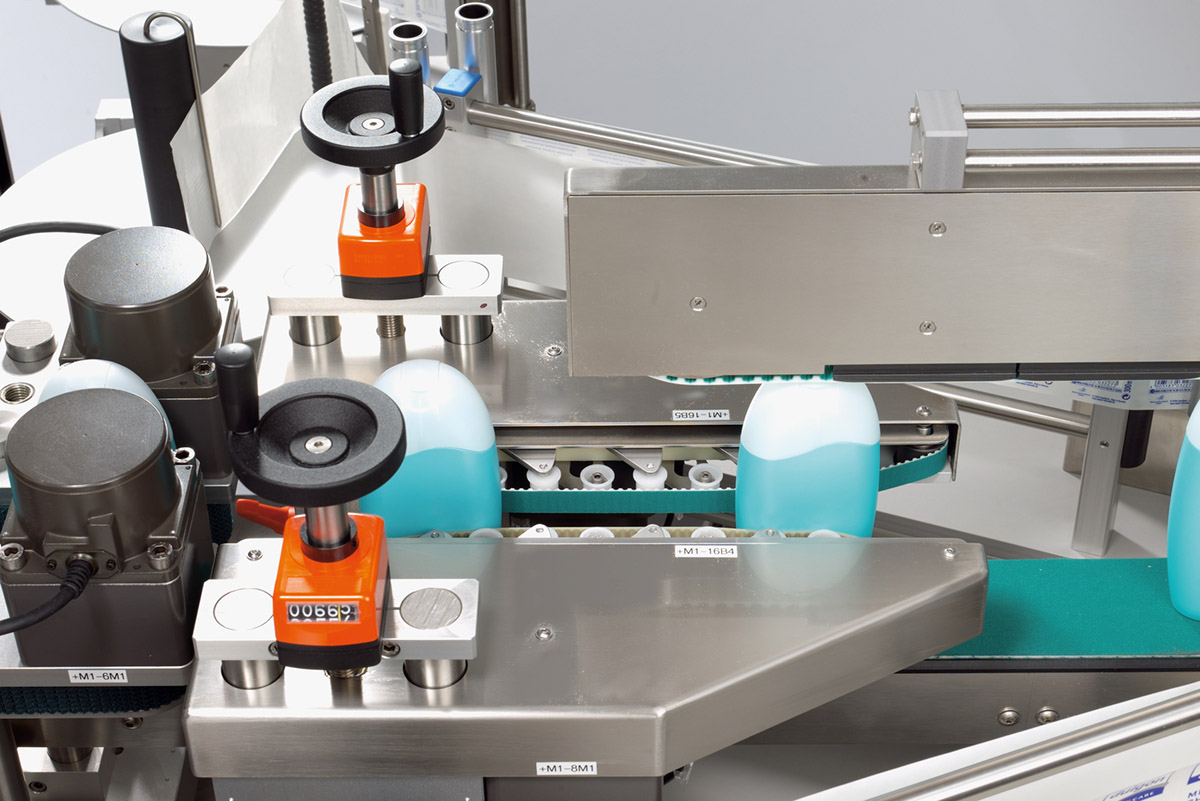

Two-side labeller HERMA 362M: labelling challenging product shapes

362M: Two-sided labelling with maximum precision

- For labelling challenging product shapes

- The 362M two-sided applicator allows you to label up to 200 products per minute

- Versatile, robust and extremely precise

- Precise labelling in the centered position is also possible as an option

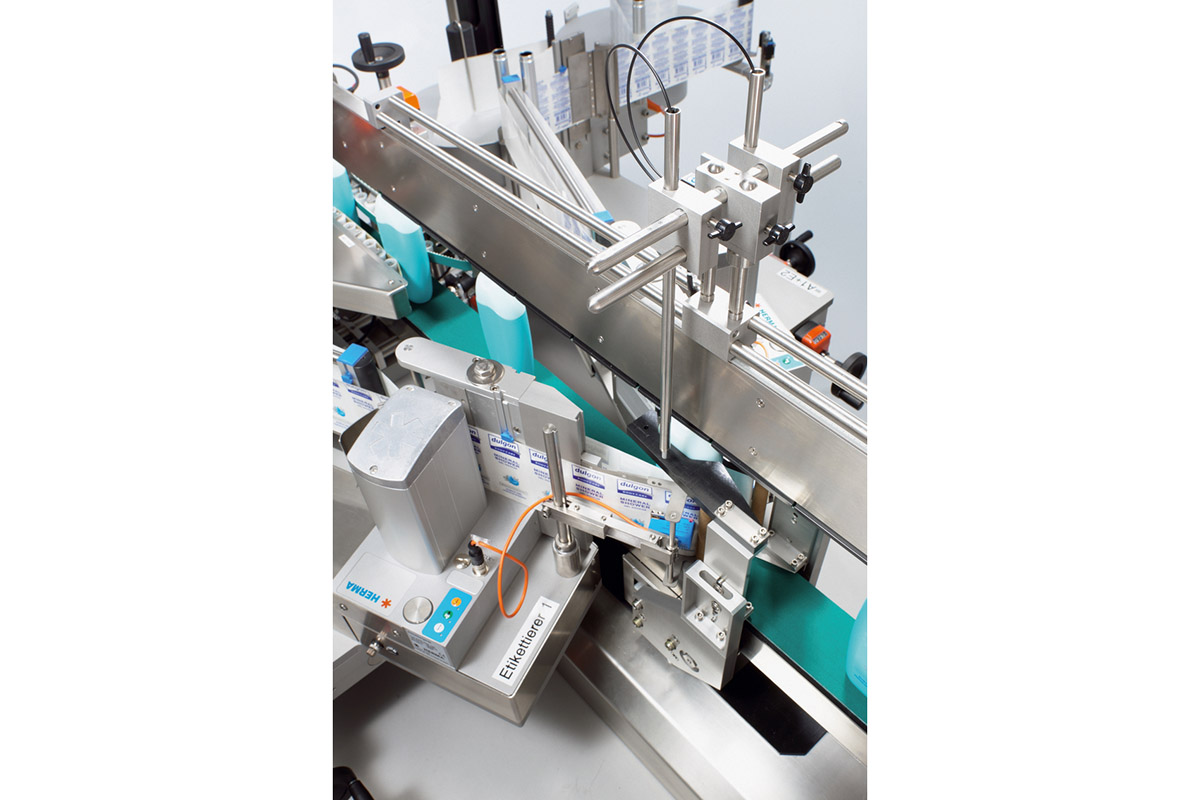

- Two high-performance applicators ensure maximum throughput, even during continuous operation

- The labelling machine can be converted for wrap-around labelling in no time at all

- With an operating concept for quick format changes and a variety of equipment options, the 362M leaves nothing to be desired

- For the highest product quality thanks to various print and label presence controls in conjunction with bad label return and product ejection features

The 362M puts an end to compromises

Thanks to applicators that operate at an outstanding speed, an operating concept that enables quick format changes and industry-specific equipment options that leave nothing to be desired. If required, the machine can also label products with difficult shapes when they are centered. On top of that, it can also be easily converted to wrap-around labelling.

Best results & useful options

- Two high-performance applicators ensure maximum throughput – even during continuous operation.

- Safe product guidance at any time, even for products with unusual shapes.

- Reliability, cost-efficiency and investment safety are ensured by the unique modular design of HERMA labelling machines with standardised components.

- When handling complex products, special centering devices ensure very precise label positioning. With the electromechanical FS03 label sensor even transparent labels can be processed smoothly.

- Electronic position indicators and motorised height adjustment support quick format changes and enable very short set-up times.

- To safeguard product quality, the machine can be equipped with print and label presence checks combined with a label return for misprinted labels and a product reject station.

Technical data

|

Labelling type: |

Two-side labelling • wrap-around labelling (optional) |

|

Product specifications: |

Rectangular, flat-arched to oval, cylindrical, free-standing |

|

Product dimensions: |

Two-side labelling: 25 - 110 x 25 - 80 x 50 - 320 mm (L x W x H) / Wrap-around labelling: 25 - 80 x 50 - 250 mm (D x H) |

|

Label dimensions: |

Two-side labelling: 15 - 240 x 30 - 200 mm (W x L) / Wrap-around labelling: 15 - 240 x 30 - 315 mm (W x L) |

|

Capacity: |

Up to 200 products/minute |

|

Power supply: |

400 V, TN-C-S, 50 Hz, 3 phases, 208 V, Delta 4-wire, 60 Hz, 3 phases (optional) |

|

Compressed air supply: |

6 bar |

|

Printer: |

Various hot-foil and thermal transfer printers (optional) |

|

Components: |

Control panel with 12 inch touchscreen, conveyor belt, side guides for products, top belt, applicators, wipe-down station |

|

Options: |

Transfer plates at infeed and outfeed, belt-type separator, scroll-type separator, chain aligner, wrap-around labelling with wrap-around belt and counterpressure plate or vertical moving roller prism, movable version, electronic position indicators, motorised height adjustment, pre-centering station, centering station, print check, bad label return, label presence check, product reject station, transparent safety guard, remote service via internet |

|

Note: |

If optional features are chosen, the above data may vary |

All series at a glance

Our 362 Master series two-side labeller offers a wide range of equipment options with various print and label presence checks in combination with bad label return and product rejection. Highest product quality is guaranteed! In the following overview you can see all series of the 362 with the most important criteria at 1 glance. If you have special safety requirements for your labelling application, our Tamper-Evident and Heathcare variants might be of interest. All our series including the Compact (362C) and Economy (362E) series can be flexibly converted to wrap-around labelling. If you have any questions or are interested, please contact our team of experts for a consultation.

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.