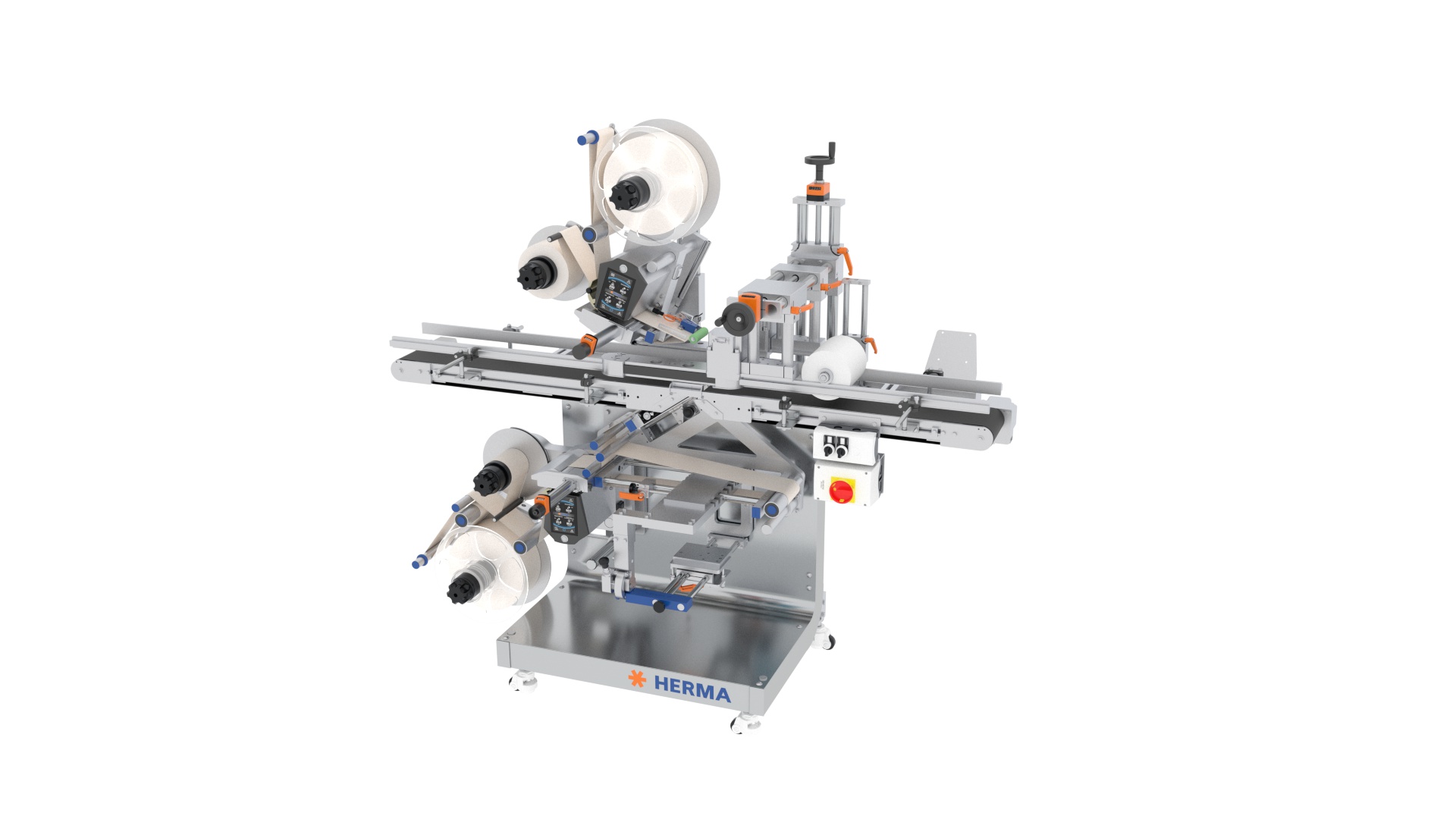

Top and bottom labeller HERMA 652C: efficient & productive

Two-in-one labelling solution

- A variety of optional modules for any labelling task

- Equipped with the HERMA 500

- Top and bottom labelling in one cycle

- Easy to integrate into any kind of production line

- Extremely efficient and highly productive

- Space-saving, compact and hugely versatile

- Also suitable for top or bottom labelling only

The 652C makes no compromises

Top and bottom labelling in one cycle – that is what makes the 652C so particularly efficient and productive. It retains all the benefits of top and bottom labelling machines, but remains compact and highly flexible when used with two HERMA 500 units. It delivers the best labelling results and can also be used to provide top or bottom labelling only if necessary. The 652C sets new benchmarks in quality, precision and efficiency, and can also be customised based on our modular system. Naturally, it can also be adjusted to different product formats with ease.

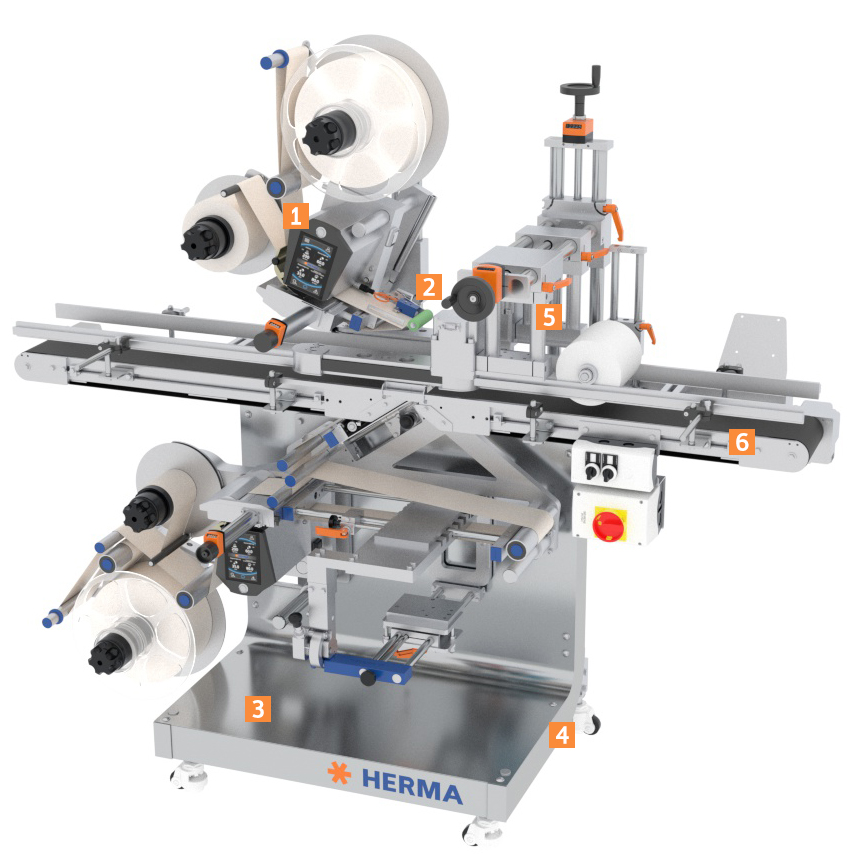

1. Ultimate performance thanks to the HERMA 500

The new HERMA 500 gives you peak performance in every regard. Innovative touchscreen menu navigation and cutting-edge interfaces tailored to Industry 4.0 are just some of the highlights of this pioneering technology.

2. Precision label scanning

The FS03 with automatic label detection scans the last label on the dispensing beak to guarantee maximum precision

3. Shortest delivery times

Thanks to their modular design, the labelling machines can be delivered in the shortest of times

4. Flexible installation locations

All the models can be supplied as mobile versions, allowing you to position the machine wherever it is currently required

5. Printing variable data

It is also easy to integrate a hot-foil printer for printing variable data

6. Adapted to your requirements

The machines can be supplied with a variety of conveyor belt dimensions, which means they can be configured for a huge range of applications

Technical data

|

Labelling type: |

Top labelling • bottom labelling • top & bottom labelling |

|

Product specifications: |

Rectangular, dimensionally stable |

|

Product dimensions: |

Top & bottom labelling: 50-300 x 10-250 x 38-300 mm (L x W x H) |

|

Label dimensions: |

Top labelling: 15 - 160 x 30 - 300 mm (W x L) • Bottom labelling: 15 - 160 x 30 - 300 mm (W x L) |

|

Capacity: |

Up to 250 products/minute |

|

Power supply: |

230 V, 50 Hz, 1 Phase |

|

Compressed air supply: |

6 bar (optional) |

|

Printer: |

Various hot-foil printers (optional) |

|

Components: |

Conveyor belt, side guide for products, applicator(s), control panel |

|

Options: |

HERMA basic or HERMA 500, Transfer plates at infeed and outfeed, moveable version, digital position indicators, various belt options, side belts; thermal transfer or hot foil printers, counter-pressure roller, post-application wipe-down roller, peel plate pivot pneumatic |

|

Note: |

If optional features are chosen, the above data may vary |

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.