With Clean Design, HERMA is taking its successful modular concept for labelling machines to a whole new level. The Clean Design concept isn't just about improving appearance, the aim is to improve the overall engineering of the machine in every respect, resulting in a number of benefits to the users.

Discovering the benefits in more detail

The new Clean Design concept is so well engineered that it opens up a number of new opportunities for our customers. Not only does it improve ordering and configuration processes, it enhances our customers' operational practices.

![[Translate to English:] HERMA Verfgbarkeit](/fileadmin/Etikettierer/Produkte/Clean_Design/Verfuegbarkeit2.jpg)

Short response times and delivery times are often the key criteria for our customers when purchasing labelling machines. To achieve this, the Clean Design machines are based on a uniform machine platform with standardised interfaces. This offers maximum flexibility for every user.

![[Translate to English:] CE-UL-konforme Version](/fileadmin/Etikettierer/Produkte/Clean_Design/EU-US_Version.jpg)

Every standard Clean Design machine is designed to have an equivalent EU and US version, i.e. a CE-compliant version with a declaration of conformity or a UL-compliant version to be submitted for UL authorisation. This makes it easier for multinational companies in particular to standardise procurement and production processes across locations.

![[Translate to English:] Einfache Reinigung](/fileadmin/Etikettierer/Produkte/Clean_Design/Reinigen.jpg)

Clean Design machines offer greater protection against contamination. This is because they have fewer dead spaces, gaps, grooves and boreholes that need to be sealed.

![[Translate to English:] Zusatzausrstung im Standardumfang](/fileadmin/Etikettierer/Produkte/Clean_Design/Standart.jpg)

A number of useful features such as the height-adjustable wrap-around station, printer integration, side belts and wrap-around rollers are no longer expensive custom solutions. They are often standard components for Clean Design machines, and are therefore more readily available and at lower cost.

![[Translate to English:] Nachhaltig und Zukunftssicher](/fileadmin/Etikettierer/Produkte/Clean_Design/Nachhaltig-Zukunftsicher.jpg)

We use aluminum profiles produced in high volumes for our Clean Design machines. This is significantly more sustainable than machine-specific bench pedestals. As the Clean Design concept also contributes to the digitisation of internal processes, further resources are saved as a result. And since function modules can be retrofitted easily, Clean Design machines are a particularly safe investment for the future.

![[Translate to English:] Einfacher Transport](/fileadmin/Etikettierer/Produkte/Clean_Design/Hubwagen-Transport.jpg)

Also Clean Design machines without rollers can be set up and moved around more easily and safely using a pallet truck. With an attachment on the front of the platform on the machine frame for a standard pallet truck, transport becomes much more stable and secure.

![[Translate to English:] Konfigurator - Digitale Auftragsabwicklung](/fileadmin/Etikettierer/Produkte/Clean_Design/Online_Konfigurator.jpg)

A newly developed online configurator enables our consultants to communicate with you directly, configure even complex labelling machines immediately on the screen and display individual functions. This creates greater clarity for the customer. In addition, linking digital order processing to the configurator ensures that customer requirements are implemented in the shortest possible time. The configuration can also be exported as a tabular overview to a PDF document.

![[Translate to English:] Verkrzte Lieferzeit](/fileadmin/Etikettierer/Produkte/Clean_Design/Lieferzeit.jpg)

Thanks to Clean Design, function modules can be used universally, i.e. across different machines, and are pre-assembled in larger quantities. This increases availability, speeds up assembly and shortens the overall delivery time. Function modules can be replaced or retrofitted more quickly during servicing.

Digitized processes at every stage

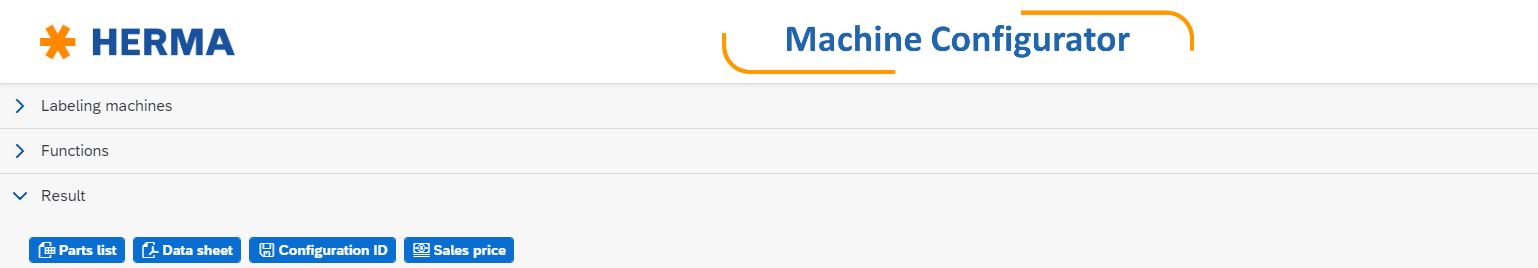

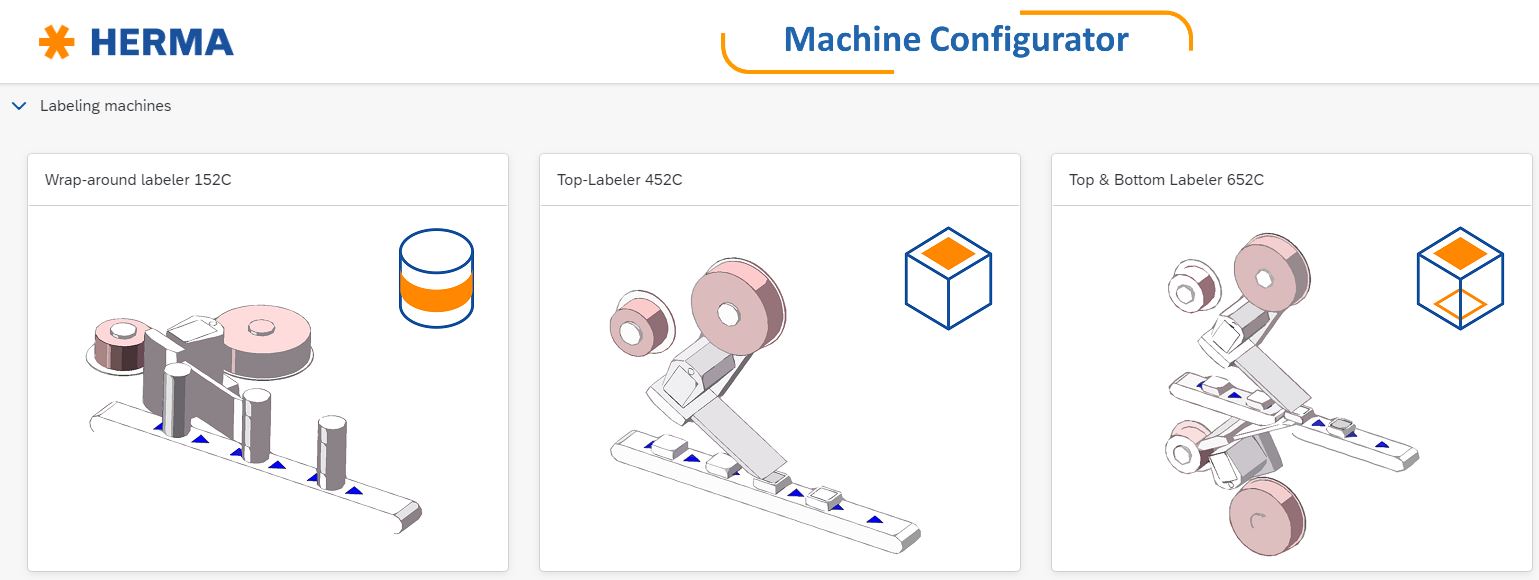

When implementing a Clean Design system, customers can benefit from fully digitized order processing, even during the configuration phase. Thanks to the new machine configurator, you can see exactly how your machine will be configured on the screen as you discuss your requirements with one of our consultants.

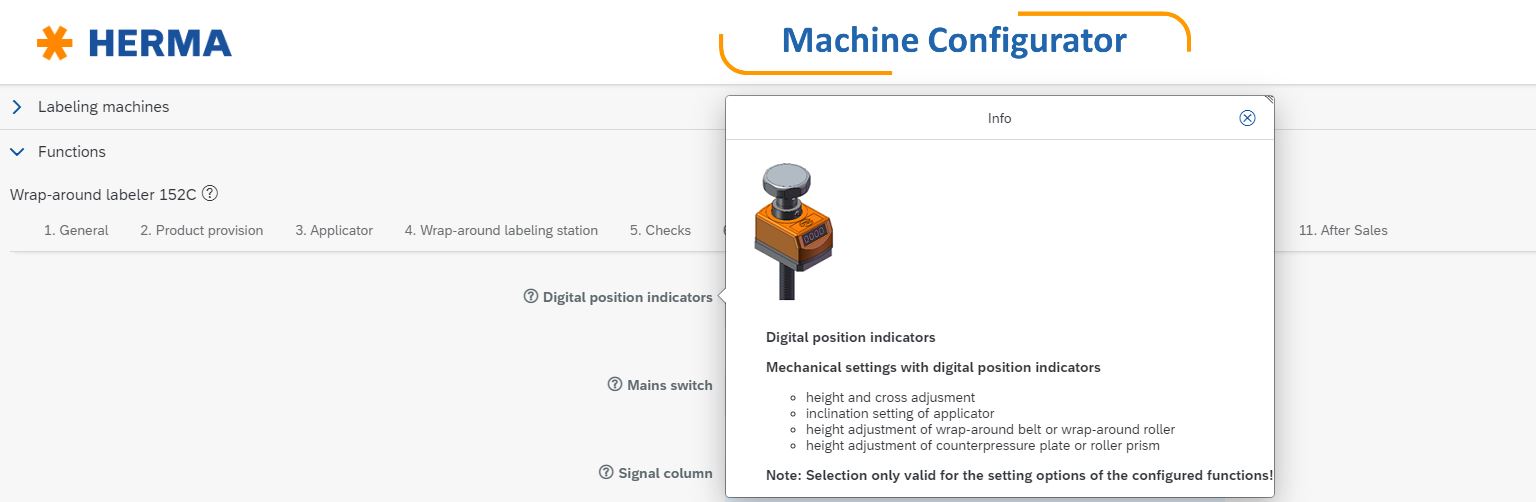

The configurator maps all dependencies of the functions and contains illustrations and written instructions for the respective functions. Plus, the configurator calculates the total costs for the chosen design and creates a corresponding overview of the individual items.

A functional overview is then created in the form of a PDF. Digitisation provides greater clarity, even during the configuration and ordering process. As a result, the labelling machine is available and ready for use more quickly.

Make an appointment right now and experience the Machine Configurator for yourself in a conversation with our sales department.

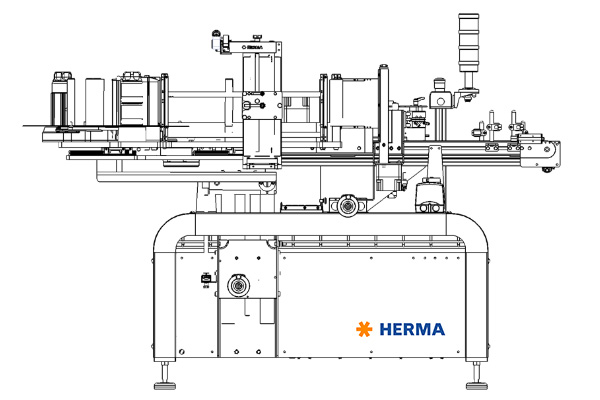

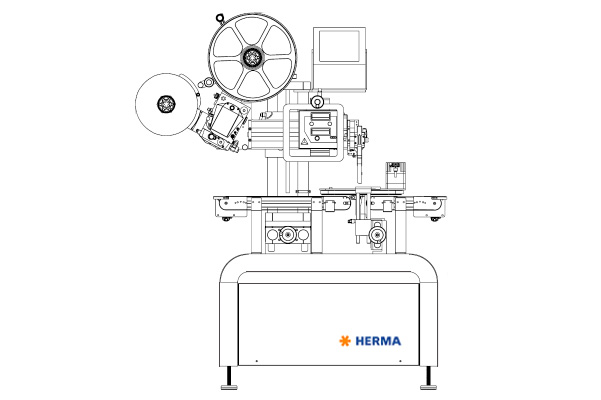

New Clean Design machines available very soon

The Clean Design is available in the 152C wrap-around labelling machine and the 752C closure labelling machine. However, all C, E and M-series machines are being gradually converted to the new design. Our 250 experts, who at HERMA focus exclusively on labelling technology, are working on these developments.

Contact

Do you have questions about the new Clean Design concept? Are you facing new challenges or simply have a question about one of our machines? The best way to contact us is with our contact form. We'll get back to you as soon as possible.

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.