Are you looking to make pharmaceutical product labelling more reliable, cost-effective, and faster? Robotics can play a pivotal role in achieving these goals, especially if products are fed and removed manually which may be labor-intensive and susceptible to errors. With the robot-assisted labelling cell 211R HC, HERMA shows how challenges in wrap-around labelling of label material can be solved more effectively. Discover the advantages of our HERMA 211R HC labelling solution.

What makes the 211R HC labelling cell so beneficial?

- The use of robotics optimizes efficiency, due to reduced downtime and consistently high performance over a long period of time.

- It minimizes operator-based errors, such as those resulting from a loss of concentration during monotonous, repetitive tasks.

- The 211R HC also helps to reduce costs, for example by eliminating time-consuming manual reworking.

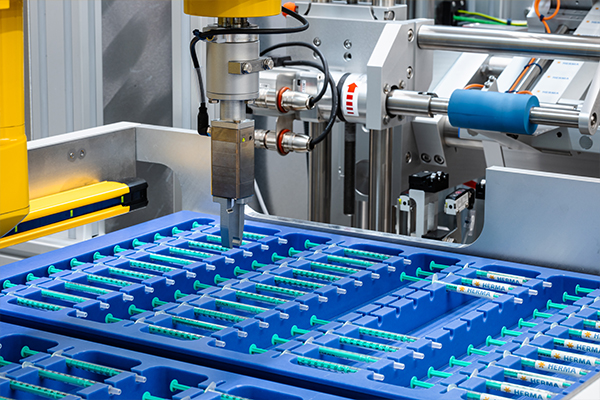

- The products are fed in and removed via an innovative drawer system. This enhances process reliability by maintaining a closed system that does not need to be opened during operation. This design ensures products are fed in and removed efficiently, minimising the risk of errors and contamination.

- The 211R HC labels up to 20 products per minute - and is 25 percent faster than a comparable conventional, semi-automatic labelling machine.

- The integration of robotics allows cost-intensive workers to focus on higher-value activities ensuring better operational continuity even during staff shortages.

- In terms of product security and machine safety: the robotic labelling cell can be programmed to automatically comply with certain labelling regulations and standards.

- For frequently changing products with varying dimensions, optional format parts with a quick-change unit are also available. This feature enables fast and efficient changeovers, reducing machine downtime.

Labelling cell with robot - ideal for small batch sizes and complex shaped products

The labelling cell is specially designed for pharmaceutical products such as small vials, pens, syringes and cartridges. These are usually non-stable and irregularly shaped. In small batch sizes these type of products have usually been labelled by a semi-automatic labelling machines, such as the conventional wrap-around labeller 211 HC. The new labelling cell however, significantly automates this process, enhancing efficiency and precision and thus represents a pioneering labelling solution.

Efficient robotic solutions for labelling syringes

Labelling syringes with precision and speed is crucial in the pharmaceutical industry, where accuracy and compliance are non-negotiable. The robotic labelling cell offers a cutting-edge solution for labelling syringes efficiently, even in high-volume production environments. This automated system is specifically designed to meet stringent syringe labelling requirements, including exact label placement, traceability, and hygiene standards. Whether you're scaling up production or optimising existing lines, our technology ensures that your syringe labelling requirements are met with unmatched consistency.

The development and functionality of the 211R HC

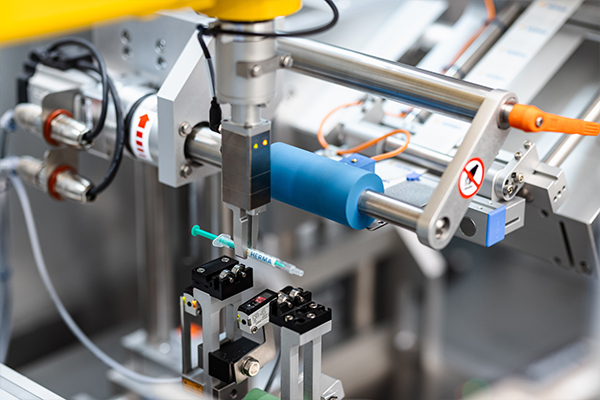

The 211R HC is the result of a developmental partnership with Fanuc and Weiss Robotics. With a special emphasis placed on minimising the footprint, the design incorporates a robot with an ultra-compact base and the world's smallest servo gripper integrated. HERMA collaborate with all leading robotic suppliers and develop solutions for a wide range of labelling applications. Thanks to its innovative design and collaboration with leading robotics providers, the HERMA 211R HC enables seamless integration into existing production lines. This increase in efficiency and high labelling precision make it an ideal solution for the demanding labelling applications of medicines and pharmaceuticals. With the 211R HC, you can optimise your labelling processes while ensuring the safety and quality of your products.

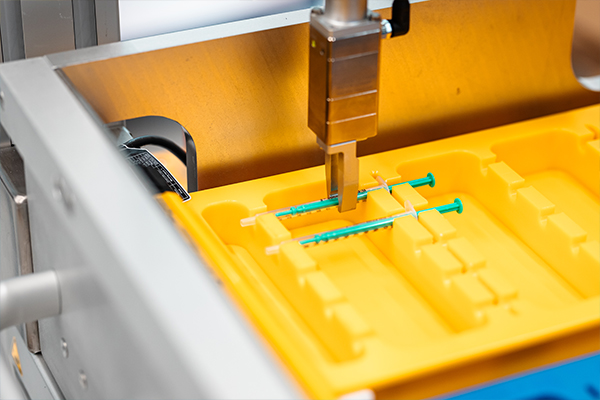

Step 1: Non-labelled products are fed directly into the trays of the closed labelling cell via a drawer. The safety cover does not need to be opened for this. This innovative approach boosts efficiency, increases safety and ensures a smooth workflow.

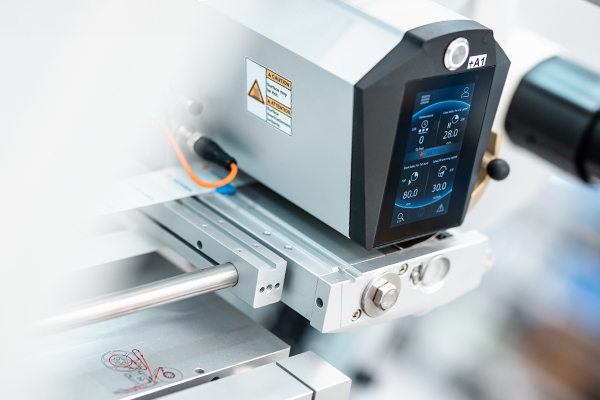

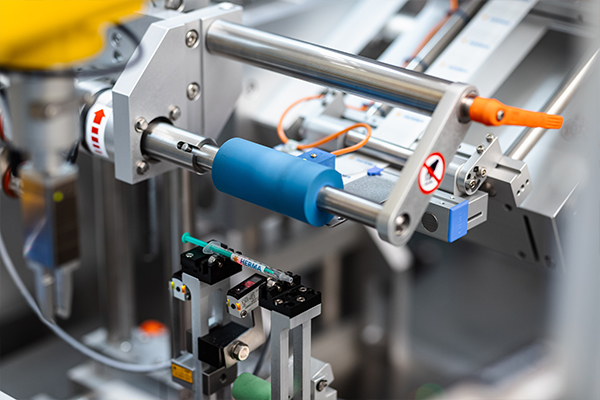

Step 2: The robot removes the products individually from the tray and places them precisely in the labelling station, which is equipped with a HERMA 500 labeller.

Step 3: The product is rotated in a engine-driven roller prism and the label is dispensed precisely onto the product at the peel-off edge, with or without label product orientation.

Step 4: After the fully automatic labelling process, the robot places the labelled products under a vision system or sensor to check the presence and variable data of the labels.

Step 5: The robot places confirmed products into a designated carton or outer tray. When it is full, it can be easily replaced using the drawer system without interrupting the labelling process.

Step 6: Unconfirmed products are placed in a separate tray.

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.