Robotic handling and automation solutions require experience, system understanding and precision. As an experienced partner for demanding automation tasks and a pioneer in product and packaging marking, we know what is important for efficient production processes. And we develop tailor-made solutions that increase your productivity and cost-effectiveness. Make your best choice with us!

With our new, robot-assisted labelling solutions for demanding pick-and-place applications, we are setting new standards in automation, flexibility and process reliability. To achieve this, we combine our expertise with the strengths of leading global partners for high-performance industrial robots.

Reliable handling where standard solutions fail

We support you exactly where you need us

From consulting and planning through implementation and commissioning to service-supported continuous and long-term operation: Relevant industries around the world, such as the pharmaceutical, cosmetics, fast-moving consumer goods, food and beverage industries , rely on HERMA's expertise in mastering constantly new challenges.

The most effective solution for continuously increasing productivity and flexibility is fully integrated automation with increased use of robotics. As a globally certified and leading manufacturer of labelling technology with proven handling expertise, HERMA can cover all requirements: with modular standard solutions as well as with customer-specific automation projects and individual designs. The focus is on maximum efficiency - without compromising on reliability and safety.

You really benefit from these advantages

- Customised complete solutions - from feasibility analysis to finished integration

- Choice between different robot and gripper systems

- Short changeover times, maximum flexibility

- Flexible use for a wide range of products

- In-house Innovation Lab at the HERMA competence centre - including realistic simulations and fast feasibility testing

- Fast amortisation and convincing ROI

- Consulting, development and implementation - all in one efficient process

Always a solution thanks to diversity and variability

Six-axis robots - maximum freedom of movement for complex processes

- enable three-dimensional motion sequences with high precision

- ideal for demanding labelling tasks in confined or varying environments

- are characterized by their enormous flexibility, for example with irregular geometries,

variable product sizes or changing pick-and-place positions

Linear systems - fast, stable, low-maintenance

- impress with their particularly high repeat accuracy at equally high speeds

- are ideal for processes where precision is required on a linear axis -

e.g. when labelling in series or processing several products in parallel. e.g. when labelling in series or processing several products in parallel - Their robust design makes them particularly durable and reliable -

with efficient use of the available installation space

SCARA systems (Selective Compliance Assembly Robot Arm) - compact, dynamic, efficient

- are ideal for fast, repeatable movements in two planes -

with a compact design - are used wherever the highest cycle rates are required in a small space

- e.g. in the packaging, electronics or food industries

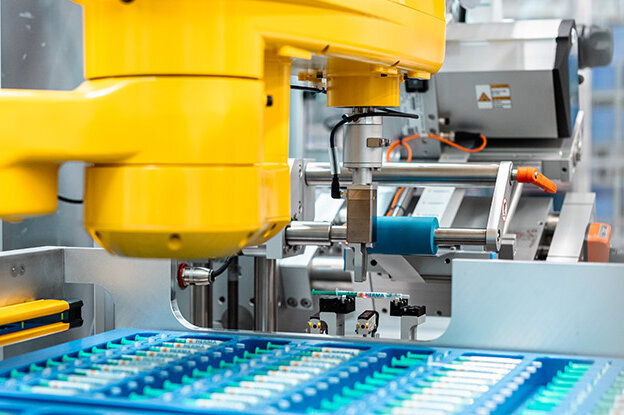

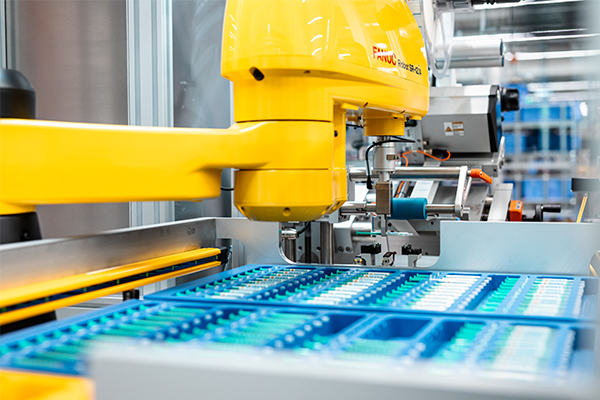

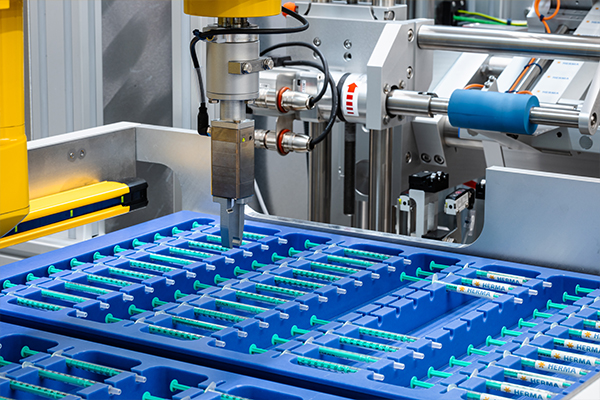

Automation examples for the pharmaceutical industry

The robotic labelling cell 211R HC for wrap-around labelling is specially designed for pharmaceutical products such as small vials, pens, syringes and cartridges. A variety of possible configurations makes it highly flexible for applying different types of labels and printing variable data in the form of barcodes, serial numbers and expiry dates. The 211R HC can also be optionally equipped with standard hot foils, thermal transfer and laser printers as well as camera systems. Thanks to its simple scalability, it adapts quickly to future requirements and is therefore particularly future-proof.

Find out more about the 211R HC robotic labelling cell here

Another example shows a robotics unit for handling pens in the pharmaceutical industry. The universal robotics module precisely grips, aligns, and places the products—without any manual feeding, which can quickly become a bottleneck. Flexible automation solutions ensure a constant, high-performance product flow and demonstrate that HERMA not only provides labelling solutions but also implements independent handling and automation concepts.

At home in the wide world of goods

HERMA technology is always as adaptable as the variety of products and packaging to be labelled requires. No matter which shapes, (surface) areas, design specifications or marketing aspects play the main role: We always combine maximum productivity with uncompromising quality.

What the experts say

Your next step—the short way to reach us

In our competence centre, we test and simulate your requirements in a practical manner. You will quickly receive a reliable concept with maximum planning security. Request your test simulation - fast, non-binding and customised.

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.