HERMA distinguishes between applicators and labelling machines. What’s the difference? In brief, applicators (HERMA 500, HERMA eco) supply and remove labels, and lie at the heart of labelling machines, which in turn provide all the additional components for labelling tasks. For many applications, absolutely precise labelling along with high repeatability is crucial. With an overall very compact design for flexible integration in clocked lines, our HERMA 500 MB labelling solution with movable peel plate is the best choice especially for machine builders.

Applicator

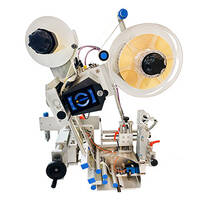

Applicators serve to transport the label web to the dispensing beak, which is where the labels are removed from the backing paper. The remaining backing paper is then rolled up. Applicators generally include an unwinder, label sensor, dispensing system, base unit, and rewinder. The drive for transporting the label web is located in the base unit of the applicator. Applicators do not include a system for supplying products.

The state-of-the-art HERMA 500 applicator is the most recent model and successor of the bestselling HERMA 400 model. The HERMA eco completes HERMA’s series of automated applicators.

HERMA applicators lie at the heart of labelling machines.

Labelling machines

Labelling machines provide a comprehensive solution for labelling tasks. Comprehensive labelling machines include a transportation system for supplying the products to the labelling station, which employs the previously mentioned applicators and then forwards labelled products to the next machine or for manual removal. HERMA’s labelling machines also have several optional features, including separation, alignment, stabilisation, review, and rejection of individual bad products, if necessary.

These machines are designed for side labelling (one or two side plus L- and C-shape labelling), wrap-around labelling (positioned to a specific feature), as well as top and bottom labelling of products. Typical models of this type of machine include the models 132M, 040M (both for wrap-around labelling), 362M, 362E, 362C (for side labelling), 152C and 152E (also for wrap-around labelling), 452C, 552C and 652C (for top and bottom labelling). Additional options and custom solutions are available upon request.

Manual label dispensers

The HERMA eco fix is a special applicator model. Labels are manually removed, taken from the dispenser and then applied to the products.

Semi-automatic units

The semi-automatic labelling machines manually supply and remove products. A transportation system for products is not included. The labelling process is triggered by two-hand operation or a foot switch. This class of labelling machines includes the 414 for top labelling and the 211 for wrap-around labelling of horizontal products.

Print and Apply systems

These systems include a printer that transports the labels. The printer applies the desired information to the labels and then sends them to a transfer unit which applies and presses them onto the respective products. Printing and applying shipping labels to boxes is a standard application of these systems.

Contact

Find the labelling machine for your needs now: From food products to pharmaceuticals and consumer goods, we offer the perfect solution for all industries and requirements – whether you need high-speed or manual labelling or wrap-around, two-sided or seal labelling.

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.