OPC UA

The OPC UA server is generally integrated in every HERMA 500 applicator, but must be activated in order to use it.

For subsequent activation, please contact our customer service. Or via E-Mail under service-machines(at)herma.com

You can view options already activated in your HERMA 500 in its "Imprint" menu.

Prerequsites

- The OPC UA-server is activated for your HERMA 500

- The OPC UA-server is activated via parameter 620 in the „Extended settings“ menu.

- The OPC UA-server is specified via parameter 621 in the „Extended settings“ menu.

- The IP address is specified via parameter 610 in the „Extended settings“ menu.

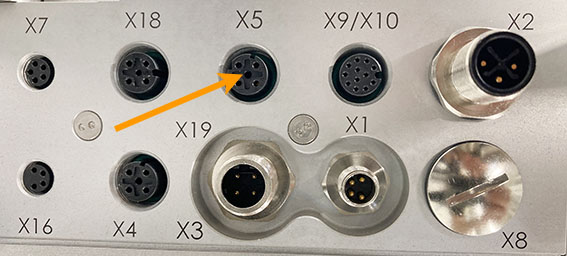

- The HERMA 500 is connected via Ethernet at X5 with a RJ45 connector.

For parameter settings, you must be logged in with operator level 4 (default setting „4444“)

V1 (until end of 2021)

V2 (Facelift) as of 2022

Default settings

OPC UA-Port: 16664

IP-adress: 192.168.3.11

Opc.tcp://192.168.3.11:16664

Note on performance and operation on the display:

The internal system load in the HERMA 500 and thus the dynamics or the reaction speed on the internal display depend on the number of subscribed objects and the respective sampling interval. If more than 10 parameters are to be monitored, it is recommended to subscribe to the complete parameter array and to perform the individual parameter evaluation on the control side. For the sampling rate, 50 ms is theoretically possible. Practically this is not necessary and a rate of about 1 second is recommended. This means that the reaction times on the display are hardly noticeably delayed and operation is possible as usual.

Data structure

Objects

Server

-

Parameters

- Single

- Individual listing of all parameters. Parameters can be subscribed to individually. If several parameters are to be subscribed to cyclically or on change, it is recommended to access the arrays.

- Array

- Parameterarray: Array with all parameter values one after the other.

- MetaData:

- Numbers: Array with all parameter numbers in a row.

- Names: Array with all parameter names in a row. Names according to the set display language.

- BaseUnits: Array with units of the parameter values.

- MinValues: Array with the minimum permitted input values.

- MaxValues: Array with the maximum permitted input values.

- DecimalPositions: Array with the respective decimal places of the parameter values.

- MinAuthorizations

- IsReadOnlys: Array with marking of all read-only parameters.

- Single

-

Status Data

- ByType

- StatusType 0

- StatusType 1

- StatusType 2

- StatusType 3

- StatusType 4

- StatusType 5

- StatusType 6

- StatusType 7

- StatusType 8

- StatusType 9

- …

- StatusType 31

Status DataV2 (as StatusData, but without empty fields)

- ByType

-

Alarm

- ID: Current number of the message. The client can initiate the acknowledgement process by writing a zero.

- Severity: Distinction between alarm message (red) and event message (yellow).

- Message: Text of the respective message in the set national language.

- Desciption: More detailed description of the message in the set national language.

- Solution: If applicable, suggested solution in the set national language.

Types

Views

Parameters

As can be seen from the objects, the parameters are provided individually or as an array. The parameter array contains the pure numerical values of the individual parameters. In addition, there are separate arrays with, for example, the name, the decimal point, the physical unit, etc. The respective assignment can then be made via the position in the array. Parameters and parameter numbers are equivalent to those in the HMI of the HERMA 500.

Status data

Changes as of firmware version 22.09.26:

- New object "StatusDataV2": The length of the status arrays is limited. Superfluous blocks filled with zeros have been truncated. This saves data overhead during transmission and allows faster processing on the server and client sides.

- Status type 31 contains a selection of the data from status types 3 and 4.

The status data are partly writable and partly read-only. They represent all data that is not available via parameters. The breakdown of the status data is shown below:

StatusType0: Switch applicator from standby to automatic mode

Bit 0 = 0 -> Standby;

Bit 0 = 1 -> Automatic

StatusType1: Bit 0 = 1 -> Manual label feed; Prerequisite: Parameter 759 (Extended settings -> Access -> Dispensing access) is set to 1 (PLC + external HMI).

StatusType3: Data dependent on the labelling cycle.

-

StatusType3 Data dependent on the labelling cycle

uint32 Array Block number

uint32 or Bit

Designation

Description

0

uint32

Istweg1

Total distance of 1st labelling process in xx.x mm

1

uint32

Istweg1_2

Total distance of 2nd labelling process in xx.x mm with double label

2

uint32

Istzeit1

Time in msec for 1st labelling

3

uint32

Istweg1_2

Time in msec for 2nd labelling

4

uint32

wDurchm_rolle

Diameter determined of unwinder roll in mm

5

uint32

wDurchm_rolle_Aufw

Diameter determined of rewinder roll in mm

6

uint32

Zyclus_gesamt

Time for a total cycle

7

uint32

stSchlupf_Abmittel

Difference reference value to actual value with label synchronisation

8

uint32

stEt1_lang_Mittel

Mean value of path length on label mm

9

uint32

stSt1_lang_Mittel

Mean value of path length in gap

10

uint32

stEt2_lang_Mittel

Mean value of path length on label

11

uint32

stSt2_lang_Mittel

Mean value of path length in gap mm

12

uint32

stZeit_bis_Stop

Path length label until stopping mm

13

uint32

stWeg_Et_b_Stop

Time label until stopping mS

14

uint32

Virtgesch_z

Start speed with using a master encoder m/min

15

uint32

fd_Zaehler_Register

Count register

16

uint32

Gsumme_Et1

Number of total labelling cycles

17

uint32

Gstrecke_Et1

Total distance in meters

18

uint32

I_Zyklus

Load over cycle

19

uint32

U_ZK

Current voltage intermediate circuit in V

20

uint32

I_Etikett

Load over label

21

uint32

Abw_Leist_Mittel

Mean output of unwinder

22

uint32

Schlaufi_Leist_Mittel

Mean output of loop unit

23

uint32

Aufwickler_Leist_Mittel

Mean output of rewinder

-

StatusType4 Digital Status

uint32 Array Block number

uint32 or Bit

Designation

Description

0

Bit 0

Sigital_Status

Operation on (drive in control)

0

Bit 1

Sigital_Status

Automatic mode

0

Bit 2

Sigital_Status

Manual label feed possible

0

Bit 3

Sigital_Status

Error

0

Bit 4

Sigital_Status

Serious error

0

Bit 5

Sigital_Status

Ready

0

Bit 6

Sigital_Status

Labelling process active (feeding)

0

Bit 7

Sigital_Status

IE chip addressable

0

Bit 8

Sigital_Status

CAN unwinder present

0

Bit 9

Sigital_Status

CAN unwinder ready

0

Bit 10

Sigital_Status

CAN rewinder present

0

Bit 11

Sigital_Status

CAN rewinder ready

0

Bit 12

Sigital_Status

CAN loop unit present

0

Bit 13

Sigital_Status

CAN loop unit ready

0

Bit 14

Sigital_Status

CAN loop filler present

0

Bit 15

Sigital_Status

CAN loop filler ready

-

StatusType4 Digital: No_Ready_Why

uint32 Array Block number

uint32 or Bit

Designation

Description

1

Bit 0

No_Ready_Why

Applicator not active

1

Bit 1

No_Ready_Why

CAN module no response

1

Bit 2

No_Ready_Why

Transfer state – remove Ready signal

1

Bit 3

No_Ready_Why

Reserved

1

Bit 4

No_Ready_Why

Unwinder not ready

1

Bit 5

No_Ready_Why

Rewinder not ready

1

Bit 6

No_Ready_Why

Loop unit not ready

1

Bit 7

No_Ready_Why

Reserved

1

Bit 8

No_Ready_Why

Initialisation with control not yet completed

1

Bit 9

No_Ready_Why

Ready not present

-

StatusType4: Outputs Digital_Out

uint32 Array Block number

uint32 or Bit

Designation

Description

4

Bit 0

Digital_Out IO

Not used

4

Bit 1

Digital_Out IO

X19.3-EncA

4

Bit 2

Digital_Out IO

X10.8-Printer on

4

Bit 3

Digital_Out IO

X10.5-Dimout

4

Bit 4

Digital_Out IO

X10.4-Endout

4

Bit 5

Digital_Out IO

Not used

4

Bit 6

Digital_Out IO

X10.8-Print

4

Bit 7

Digital_Out IO

No_Feed

4

Bit 8

Digital_Out IO

X10.3-Ready

4

Bit 9

Digital_Out IO

Manual label feed in progress

4

Bit 10

Digital_Out IO

X19.12-Manual feed button

4

Bit 11

Digital_Out IO

X19.8-ACK

4

Bit 12

Digital_Out IO

X15.2-Teach

4

Bit 13

Digital_Out IO

X6.2-Transfer

4

Bit 14

Digital_Out IO

X19.10-No_Label

4

Bit 15

Digital_Out IO

X10.7-Fault

-

StatusType4: Inputs Digital_In

uint32 Array Block number

uint32 or Bit

Designation

Description

5

Bit 0

Digital_In IO

X7.5 PrinterBusy

5

Bit 1

Digital_In IO

X7.4 Printer Error

5

Bit 2

Digital_In IO

X6.4 Sensor

5

Bit 3

Digital_In IO

Reserved

5

Bit 4

Digital_In IO

X10.12-ACK

5

Bit 5

Digital_In IO

X55.4 Input rewinder

5

Bit 6

Digital_In IO

X19.7

5

Bit 7

Digital_In IO

Not used

5

Bit 8

Digital_In IO

X53.2 Input unwinder DIM

5

Bit 9

Digital_In IO

X52.2 Input unwinder END

5

Bit 10

Digital_In IO

X10.6 On/Off

5

Bit 11

Digital_In IO

X19.4 Manual feed button

5

Bit 12

Digital_In IO

X19.9 Lock

5

Bit 13

Digital_In IO

Not used

5

Bit 14

Digital_In IO

X15.4-Stop sensor

5

Bit 15

Digital_In IO

X16.3-Start sensor

-

StatusType4 General

uint32 Array Block number

uint32 or Bit

Designation

Description

2

uint32

w_DriveTemp1

Temperature inside housing

3

uint32

w_DriveTemp2

Temperature IPM

6

uint32

Gsumme_Einschalt

Power-on time applicator in sec

7

uint32

Gsumme_Betrieb

Operating time applicator in sec (active control)

8

uint32

Abwick_Betriebsstunden

Operating time unwinder

9

uint32

Schlaufi_Betriebsstunden

Operating time loop unit

10

uint32

Aufw_Betriebsstunden

Operating time rewinder

-

StatusType14 Firmware/Bootloader

uint32 Array Block number

uint32 or Bit

Designation

Description

0

uint32

DSP1_FW

Firmware DSP Core 1

1

uint32

DSP2_FW

Firmware DSP Core 2

2

uint32

DSP1_BL

Bootloader DSP Core 1

3

uint32

DSP2_BL

Bootloader DSP Core 2

4

uint32

Rangierplatine_FW

Firmware distributing board

5

uint32

Rangierplatine_BL

Bootloader distributing board

6

uint32

Abwickler_FW

Firmware unwinder

7

uint32

Abwickler_BL

Bootloader unwinder

8

uint32

Schlaufi_FW

Firmware loop unit

9

uint32

Schlaufi_BL

Bootloader loop unit

10

uint32

Aufwickler_FW

Firmware rewinder

11

uint32

Aufwickler_BL

Bootloader rewinder

12

uint32

Feldbus_BL

Bootloader field bus

13

uint32

Feldbus_FW1

Firmware 1 field bus

14

uint32

Feldbus_FW2

Firmware 2 field bus

15

uint32

Reserve

16

uint32

GeräteID

Unique Number of DSP

-

StatusType31 Special data selection from other status types

uint32 Array Block number

uint32 or Bit

Designation

Description

0

see StatusTyp3-15

Count register

1

see StatusTyp3-16

Total labelling cycles

2

see StatusTyp4-0

Digital Status (resolution in bit)

3

see StatusTyp4-1

No-Ready-Why (resolution in bit)

4

see StatusTyp4-4

Digital outputs (resolution in bit)

5

see StatusTyp4-5

Digital inputs (resolution in bit)

6

see StatusTyp4-6

Power-on time

7

see StatusTyp4-7

Operating time