The labelling of snus and nicotine pouches requires the highest precision. While snus is popular in Sweden and Norway and contains real tobacco, nicotine pouches are a tobacco-free alternative that is particularly in demand in the USA. They are considered less harmful and are also freely available in the EU.

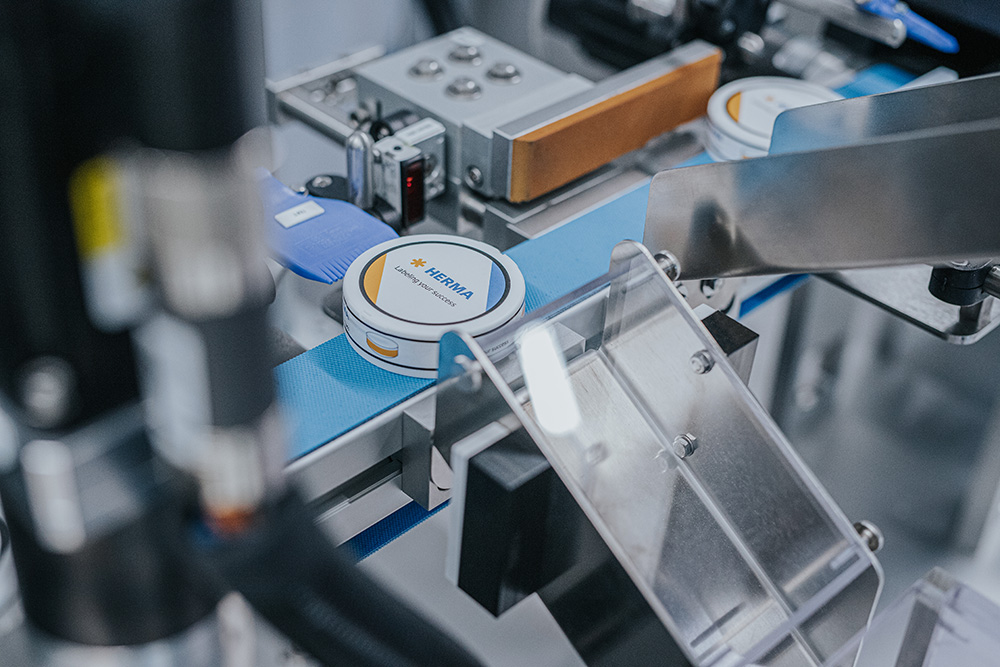

Both products are sold in small doses – so high-performance labelling machines are needed for precise, fast and centered labelling on can lids. HERMA offers customised solutions for these special requirements.

HERMA offers a number of labelling solutions that are perfect for...

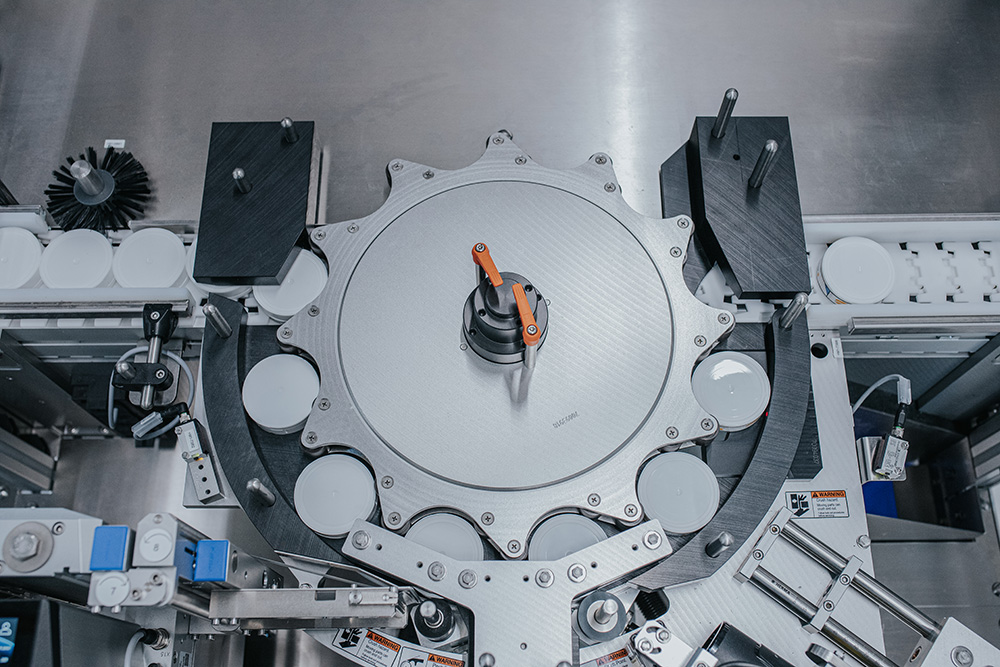

- Precisely positioning round lid and bottom labels in the centre of round can lids at high speeds

- applying long, narrow wrap-around labels at high speeds and with high precision

- if required, labelling every surface (lid, bottom and wrap-around labels) with the lowest labelling tolerances

What makes labelling round cans of snus and nicotine pouches a challenging task?

For top and bottom labelling:

One major challenge is the in-line labelling of these cans, and the exact positioning of the round labels on the can lids in particular – especially when the edge trimming for the labels is not always completely perfect.

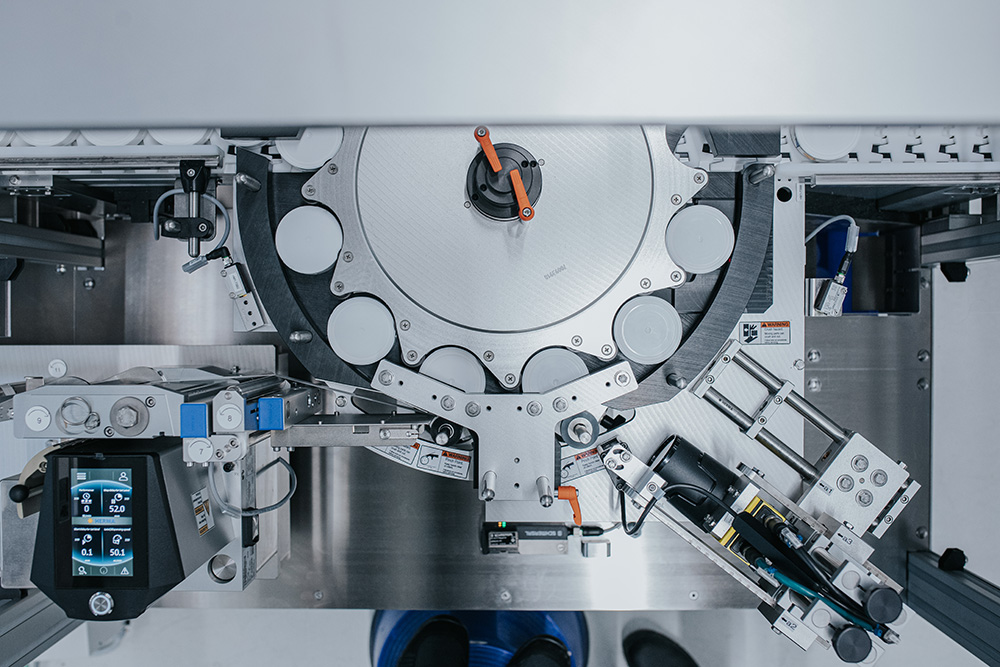

For wrap-around labelling:

Another challenge is to wrap the long, narrow label around the snus can in perfect alignment without sacrificing speed or cycle times.

Thanks to its innovative labelling solutions, HERMA manages to keep labelling tolerances at a very low level while at the same time ensuring the necessary labelling speed and precision – with maximum accuracy and reliability. Our high-performance labelling machines can label up to 200 products per minute.

Your advantages when labelling snus and nicotine pouches with HERMA labelling machines:

For the precise and clean application of top labels

- Even if the edge trimming for the labels is not 100% correct, which occurs occasionally, it can be compensated along two axes through the can positioning – by adjusting the lateral conveyor belts and changing the start delay

For the lowest possible labelling tolerances

- For example, you can choose to use the data collected on the label position to adjust subsequent products

For greater certainty in the production process with any applicator – uncomplicated and reliable

- Missing, poorly positioned or incorrect labels are recorded and bad products are conveyed into a separate box through a shaft or reject door with a blast of compressed air – a control sensor prevents them from leaving the system

Minimal set-up times and the highest possible output

- The products can be turned 180° horizontally using a C-arm turning station and then labelled from both sides by a top-label applicator --> the arrangement of the individual applicators provides excellent accessibility and ensures it is easy to change label rolls

For a smooth process and safe integration into complete packaging lines

- A sensor also monitors the product outlet for jams and stops the supply line if necessary to eliminate any faults

For longer running times and uncomplicated, user-friendly operation

- Users also have the option of configuring settings on the HMI – however, only minimal operator input is required overall

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.