Bottle labels generally have two main tasks: On the one hand, they are intended to arouse interest at the sales shelf and create incentives to buy the brand or product in question. This applies in particular to food and beverages, but also to cosmetics. On the other hand, they must safely transport necessary, often legally prescribed information - an aspect that is particularly important for pharmaceuticals and chemicals. Precision and reliability therefore play a paramount role in bottle labelling.

This is what matters when labelling bottles

High speed

A feature of labelling high-volume or small-format products is almost always high speeds. Bottle labellers should therefore have sufficient performance reserves or fast upgrade options, for example in the event that the cycle rate of an upstream capping machine is increased.

Sophisticated appearance

Bottles often carry more than a single label. In the case of two-sided labelling, possibly in combination with another bottle neck label, the visual interplay must be perfectly coordinated.

Detailed information

Wrap-around labelling makes optimum use of the space available for information. However, as the length of the labels increases, so do the demands on their handling to ensure a perfect fit on a bottle.

Challenging environment

Where liquids are filled into bottles, moisture and humidity as well as low or high temperatures are often the order of the day. To ensure that beverage labels adhere securely right from the start even in these cases, labelling machines and the label dispensers for beverage marking must be equally robust, reliable and easy to clean.

Comprehensive requirements

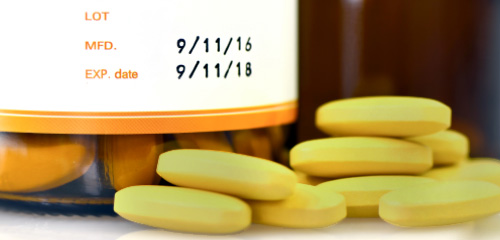

Simply applying labels to bottles is sometimes only part of the requirements. In many cases, variable or even serialised print data is added, for example by thermal transfer printing. In many cases, it must also be possible to integrate corresponding control systems and reject options.

Bottle types and label types for bottle labelling

Each industry has developed its characteristic bottle shapes and the labels to match. Some bottle shapes are now even iconic of a particular brand. For luxury products such as perfume, wine or high-priced spirits, highly refined and therefore sometimes very sensitive labels are common.

Form follows function

The number of different bottle materials is not too large. Most of them are made of glass or plastic, occasionally also of aluminum or stoneware. The shapes, on the other hand, are virtually unlimited. Depending on the application, certain types of bottles have become established for certain product categories. Whether it's cough syrup, nose drops, perfume, cleaning agents, mineral water, wine, spirits or other beverages labels, the pure function of a bottle can often be identified without a label.

The following labels are used

HERMA labelling machines process all standard labels for cosmetics products with complete reliability, including more unusual designs such as sandwich labels, 3D labels, luminescent labels and RFID labels as well as labels made from recycled materials.

Promotional labels

- Promotional label

- Multiple packaging label

- Wobbler label

Information labels

- Sandwich label

- Leporellos label

- Booklet label

Transparent labels

- No-label look labels

- Grab tabs

- 3D label

Security labels

- Tamper-evident label

- Luminescent label

- RFID label / anti-theft label

These machines are used in the labelling of bottles

Depending on the defined labelling type or number of labels, HERMA offers suitable fully automatic labelling machines or labellers for bottles. The HERMA 500 Rotary applicator is specially designed for use in rotary machines. Thanks to its particularly slim design, it can be integrated particularly easy. The 362M is ideally suited for two-sided labelling of even complex-shaped bottles. It can label demanding product shapes precisely when centered. When it comes to wrap-around labelling of small vials such as glass vials, the 132M HC is in demand. With 600 products per minute, it is designed for high batch sizes, such as those found in the healthcare and pharmaceutical sectors. In principle, many HERMA labelling machines can be equipped with several labellers if required. For smaller batch sizes, HERMA also offers hand labellers with manual operation, for example for labelling wine bottles.

HERMA labelling machines for labelling bottles

HERMA labelling machines have proven their worth in many industries for labelling glass and plastic bottles of any shape. Their high flexibility and proverbial reliability are guarantees for efficient labelling. HERMA labelling machines ensure

- due to its modular design with standardised connections, maximum freedom in the selection of serialisation, printing and control systems

- wrap-around labelling with two individual labels, the "multiple labelling function" in which both labels are on one carrier tape

- short makeready times due to the tool-free changeover of many format parts - important especially for contract labelling with changing product types

- simple and reliable integration into complete packaging lines thanks to state-of-the-art interfaces

- the use of special labels such as booklet labels, labels for the blind, or labels with braille

- compliance with GMP and FDA guidelines, foodstuffs requirements, machine guidelines and ISO9001

- optional equipment with controls from Siemens or Allen Bradley

Examples of bottle labelling with HERMA technology

Frequently asked questions about bottle labelling

Success Stories

HERMA technology is used in many industries for labelling bottles. See for yourself the challenges of some selected customers.

High precision for high-strength liquor

Learn more

Gernep labelling machines with HERMA 500 Rotary

Learn more

WALA relies on a highly flexible HERMA system

Learn more

Contact

Request for quotation

We produce labelling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labelling solution requirements on the following page so that we can give you a good consultation.