The HERMA eco applicator will celebrate its premiere at LogiMAT 2026: For the first time, it can be experienced in combination with a stroke applicator (Hall 2, Booth D11). This allows for particularly economical labelling from above while the machine is at a standstill. "The HERMA eco has generated high demand right from the start. For standard applications, it is simply unbeatably affordable in terms of its features and performance. We have thus redefined the benchmark for economical entry into leading labelling technology," says Philipp Ott, Head of Sales national & OEM for Labelling Machines at HERMA, commenting on the success of this entry-level model. "Expanding its range of applications was the next logical step for us. This also underlines once again the high modularity of HERMA systems." HERMA has installed a complete labelling line at its trade fair stand for live demonstrations of the new configuration. Using real applications, the company is showing how the right solution can be implemented for almost any labelling task. The HERMA eco can also be seen there in its "classic" application, labelling on the fly.

Unmatched in performance and flexibility

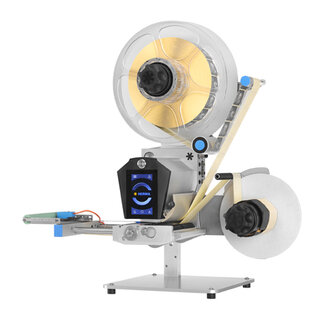

Another highlight of the labelling line is the top-of-the-range HERMA 500 model, which remains unrivaled in terms of performance, user-friendliness, and, above all, flexibility. It can handle any speed, any installation situation, and any label width. A uniquely powerful online configurator enables machine builders and system integrators to put together a HERMA 500 themselves or together with a HERMA expert according to their respective requirements. This applies, for example, to the structural width, running direction, and release systems, but also to the required speed and the type of unwinder and rewinder used.

The base unit and user guidance always remain the same. This standardisation means optimum availability, short delivery times, consistent integration processes, maximum reliability, and extremely satisfied users. Especially for logistics applications, the HERMA 500 can also be easily equipped with a standard thermal transfer printer for printing variable data.

Can be aligned in almost any direction

The HERMA Print & Apply systems are also of central importance for logistics tasks. The used components —including the printing unit, dispensing unit, and winder—can be positioned in almost any orientation, offering a wide range of options for integration into existing production lines. The proven standard components of the modular HERMA system, which are also used in high-performance labelling systems, guarantee reliable label application. At the same time, they allow for an easy modification when requirements change without the need for costly new investments.