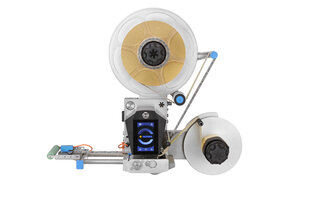

For mechanical engineers looking for a highly standardised label applicator that can be configured quickly while being easy to integrate with regard to control technology, a HERMA 500 is the ideal solution. HERMA will be presenting the full range of options for the first time at Interpack (Hall 8B, Stand C27 and at Packaging Valley, Hall 16, Stand D72-5). "The catchphrase 'one for all' applies to the HERMA 500 more than probably any other label applicator out there. The key to this is aspect the HERMA 500’s modularity, which is probably unique in the industry," says Christos Kaisoudis, Sales Manager at HERMA Labelling Machines. "It can cover any speed, any installation situation, any label width. The base unit and user navigation always remain the same. This standardisation means optimum availability, short delivery times, consistent integration processes, maximum reliability and thus also extremely satisfied users at all times. In our industry, this is by no means a given. Usually, for example, different power spectrums are realized with completely different devices." To simplify integration for mechanical and software engineers, the HERMA 500 is probably the first label applicator ever to support the Industrial Ethernet standard for Profinet and Ethernet/IP. These two real-time-capable Industrial Ethernet protocols allow the HERMA 500 to be integrated into the widely used PLC controls from Siemens, Schneider Electric and Allen-Bradley. This can eliminate considerable wiring effort along with the resulting costs. HERMA not only provides physical interfaces, but also corresponding data modules as well as information for easy integration into the respective PLC control system. Suppliers and integrators of complex filling, packaging and labelling systems can simply download this information from the HERMA Service Portal or have it included in the delivery. In real-time, these interfaces allow the control image of the applicator to be integrated into the control of a larger system.

Exceptionally short delivery times

To make the integration of a label applicator as convenient and as quick as possible from the start of a project, HERMA offers a powerful online configurator. This is how mechanical engineers and system integrators can assemble their HERMA 500 including the stand – meaning it is ready for installation – according to their respective wishes and requirements themselves or in consultation with a HERMA expert. This may apply, for example, to structural width, running direction and unwinding systems, but also to the required speed and the type of unwinders and winders used. And here’s the kicker: the corresponding CAD data will then be available for download in various output formats, meaning you can export the configured CAD model and transfer it to your own machine or line. On this basis, a data sheet with 3D visualizations for the individually configured applicator can also be created and downloaded. Another advantage is that the price of the desired configuration is displayed immediately, depending on the selected version. This makes it possible for HERMA to provide all important parameters for successful project planning and implementation virtually in real-time. Due to the automated ordering process, HERMA also promises an exceptionally short delivery time of approx. eleven business days. Once configured and perhaps also ordered, the designs can also be saved for repeat orders.

Special designs for specific requirements

For very special requirements, HERMA also offers special designs or pre-configured equipment. For example, the HERMA 500 can be used in rotary machines for the labelling of bottles or jars: the HERMA 500 Rotary is distinguished by a particularly slim design. If absolutely precise labelling with high repeat performance is required, the HERMA 500 MB, which is equipped with a movable peel-off edge, is ideal. The HERMA 500, with a full equipment variant that includes motorised winders and a loop unit, covers exceptionally high output requirements of up to 200 meters per minute. These three variants again use the same base unit as all other HERMA 500s – and thus offer the same advantages.