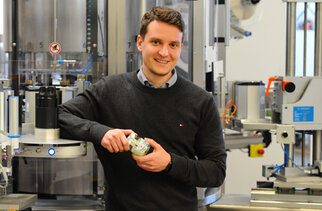

Anyone who installs a three-digit number of HERMA 500 label applicators per year is someone whose judgment carries a good bit of weight. "The simple, standardised integration of applicators into our systems and their controls, their high precision and, of course, the worldwide service that HERMA offers via its network are important foundations for this long-lasting cooperation," says Martin Hammerschmid, Managing Director of Gernep, a technology-leading supplier of rotary labelling machines. Founded almost 40 years ago and initially specialising in medium-sized breweries, rotary labelling machines from Gernep are now modular specialists for high-quality equipment in the beverage, food, consumer health-care and non-food industries – and are used in more than 120 countries. HERMA applicators have been used in Gernep’s systems for around 20 years. Precisely adapted to the special requirements of Gernep, a special design was developed, first as the HERMA 400 Rotary, then as the HERMA 500 Rotary. With its pointed shape towards the front, reminiscent of a slice of cake, it is ideally suited for use in rotary labelling machines. "The closer we get to the middle of the carousel, the slimmer the design has to be,” Stefan Kramer, Product and Project Manager at Gernep, explains. This is because more and more control systems now have to be integrated in the centre of a rotary press, for example for label presence or the correct printing of variable data. "It used to be that it was primarily pharmaceutical companies that had this re-quirement. Today even smaller breweries make use of them," says Kramer.

Automatic speed synchronisation

Clearly defined standards and interfaces such as OPC/UA facili-tate the integration of the applicators. "All devices supplied by HERMA are ready to plug in and are extremely reliable with regard to scheduling," Kramer emphasizes. Fully integrated into the Gernep machine control system, the applicators can conveniently be set remotely, for example to support end customers. Depending on customers' performance requirements, Gernep now uses three different versions of the HERMA 500 Rotary: up to a speed of 45 meters per minute, a small version that does not require motorised winders is used. The next stronger version can reach up to 75 meters per minute with engine support from the winders. The most powerful version can reach 150 meters per minute. All variants are available with one or two unwinders. This enables the operator to change to the next label roll more quickly. If machine downtimes due to reel changes are to be almost completely avoided, Gernep machines can be prepared for non-stop operation. For this purpose, all or defined applicators receive a corresponding counterpart that takes on the labelling as soon as a label roll is empty.

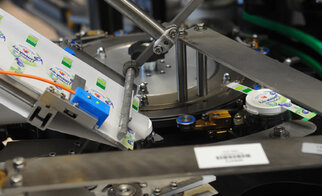

This is the case for example with a self-adhesive labelling machine from the Soluta series that Gernep has just completed for the Sterzing dairy farm and which is equipped with three HERMA 500 Rotary applicators. Gernep will demonstrate this set-up at Interpack (Hall 13, Stand D15). This production line labels up to 10,000 jars per hour, each containing 150 grams of high-quality organic yogurt. The labelling process is a demanding one. Not only must a circular label be applied onto the plastic lid precisely from above, but its two narrow sealing tabs must also be joined to the glass body cleanly and without creasing. Since the plastic lid already has a pull tab, it may not be covered. This is done by mechanically aligning the yogurt jars in an upstream starwheel. After the lid label has been applied, the jars are rotated and run past one of the two other HERMA 500 Rotary applicators to label the body of the jar. An operator can simply move the non-active applicator out of the carousel on a carriage and apply a new label roll at their leisure. There’s another factor that contributes to the precision of the labelling: Speed synchronisation takes place automatically; adjusting the height and tilt is simple and precise using a trapezoidal thread spindle and digital position indicators. "HERMA and Gernep in combination, that's always a very stable, extremely precise solution," says Simon Brandstetter, who works in Gernep’s sales department and supports the Sterzing dairy farm. The customer is also very appreciative of this, as can be seen by the fact that this is already the second system of this kind that the Sterzing dairy farm has acquired from Gernep. HERMA’s labelling technology was also used in 2014.